AI Solutions for Precision, Quality, and Innovation in Manufacturing:

Save 35% of your quality control cost

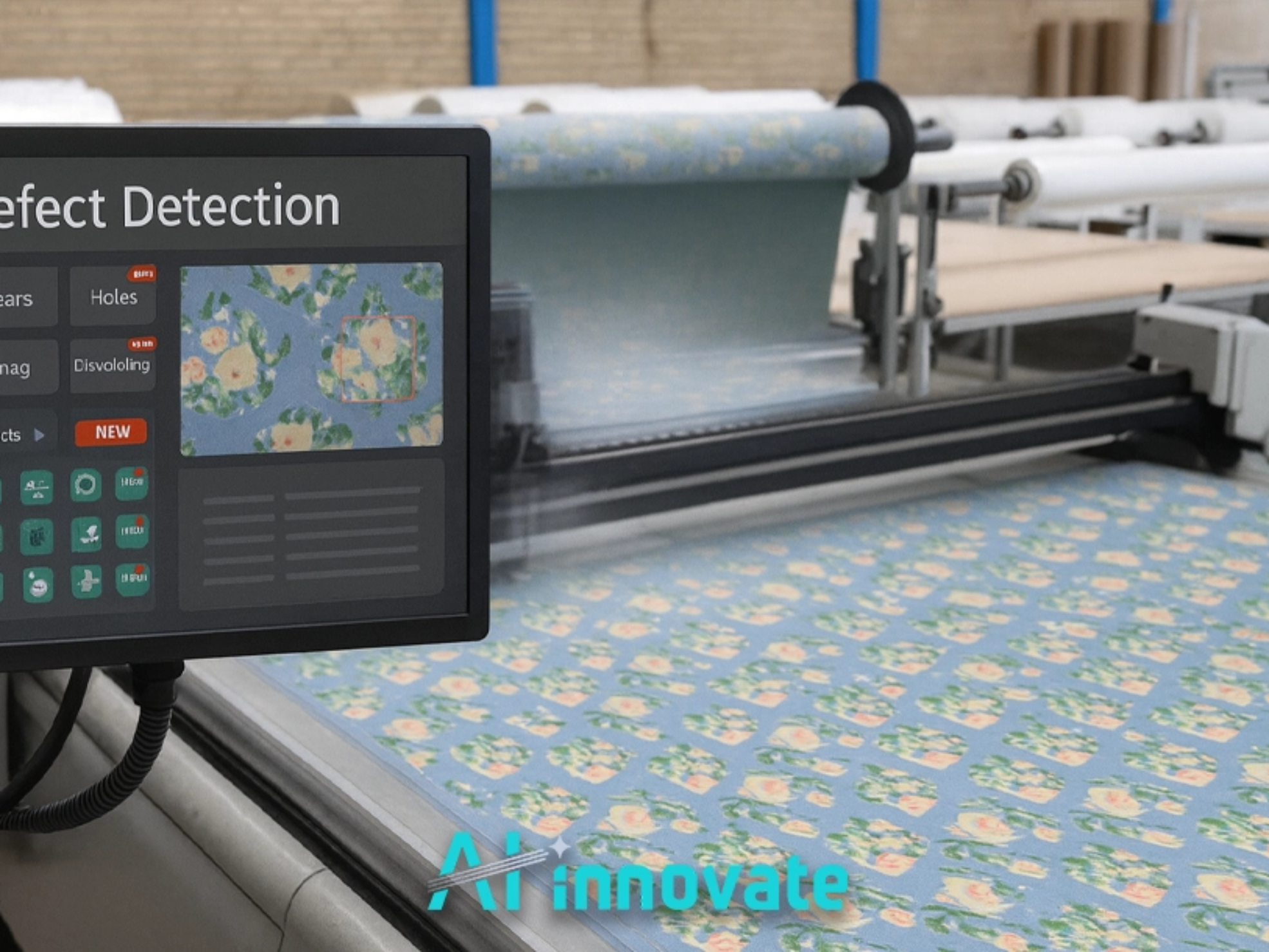

Discover the power of AI2Eye for defect detection and optimization.

Our Products

AI2Eye

Real-time defect detection and process optimization to revolutionize quality control in manufacturing.

AI2Eye Revolutionizing Quality Control

For Smarter Defect Detection and Process Optimization

AI2Eye leverages advanced Artificial Intelligence and Machine Learning to revolutionize quality control across industries. Reduce inefficiencies and human error with AI2Eye’s cutting-edge features, including:

– Real-time defect detection

– Improved operational efficiency by 30%

– Reduction in downtime by 40%

– Seamless integration into existing systems

Whether you’re in metals, polymers, packaging, textiles, or other continuous manufacturing processes, AI2Eye is your solution for smarter, faster, and more reliable quality control.

Ready to take your production line to the next level? Book a demo with us!!

Why AI Innovate

AI-Driven Precision

Detect defects with unparalleled accuracy to ensure exceptional product quality.

Cost Savings

Minimize waste, rework, and downtime for enhanced profitability.

Scalable Solutions

Adaptable to various industries, including textiles, metals, and packaging.

Real-Time Insights

Empower data-driven decisions with actionable analytics.

Expert Support

Backed by a team of AI specialists focused on solving industry challenges.

Sustainability Commitment

Optimize processes to reduce environmental impact and support greener manufacturing.

Seamless Integration

Quick and disruption-free implementation into existing systems.

Experience the Future of Manufacturing Quality Control

Schedule Your Demo Now.

Our Blog

Textile Defect Detection – AI Tools for Zero Defects

The modern textile industry operates on a challenging premise: delivering flawless products at a scale and speed that often exceeds human capability for quality ...

Textile Defect Detection – AI Tools for Zero Defects

The modern textile industry operates on a challenging premise: delivering flawless products at a scale and speed that often exceeds human capability for quality ...

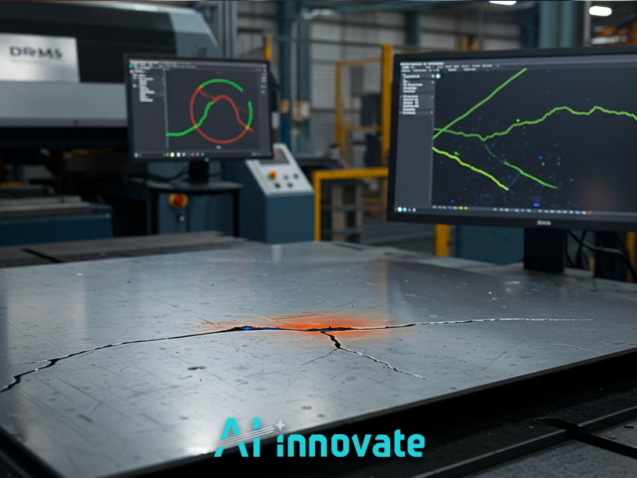

Surface Crack Detection with Deep Learning – Revolutionizing Quality Control

The structural integrity of industrial components and civil infrastructure is paramount to operational safety and economic stability. While traditional inspecti ...

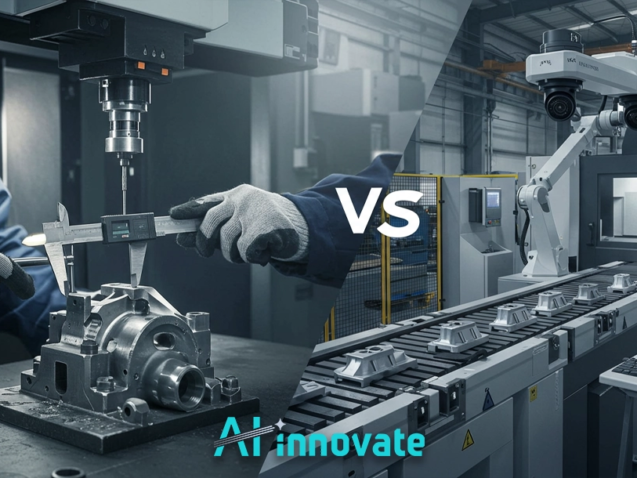

Machine Vision vs Human Inspection – Reliability in Industry

The human eye, for all its adaptability, has non-negotiable physical limits in resolution, spectral range, and consistency. In applications where defects are me ...

Contact Us

Complete the form below and our team will aim to be in touch within 1 business day.