Beyond abstract theory, Artificial Intelligence is now profoundly impacting real-world industrial processes, particularly in elevating quality control effectiveness. AI-Driven Quality Control represents this applied intelligence, solving complex manufacturing problems with data-driven insights rather than generalized automation hype.

AI-Innovate builds the practical AI and machine vision tools that make this level of precision and efficiency attainable for manufacturers seeking robust quality assurance. This piece examines how AI QC functions technically, highlights its concrete benefits in reducing waste and enhancing consistency, and discusses the practical aspects of adopting such solutions.

Next-Level Quality Control Starts Here

Let AI inspect, analyze, and optimize – faster and smarter than ever.

Foundations of AI-Powered Quality

At its core, AI-Driven Quality Control signifies a paradigm shift, moving quality assurance systems beyond fixed, rule-based approaches toward adaptive, data-centric intelligence. This offers a critical advantage over traditional statistical sampling or rigid automated checks, which struggle with subtlety and variability inherent in modern production.

The fundamental principle involves training artificial intelligence models through methods primarily rooted in machine learning. These models are engineered to process and interpret vast volumes of diverse production data—from images and sensor readings to historical performance logs. They learn to identify patterns, recognize anomalies, and make informed decisions.

Key operational principles underpinning AI QC adoption

- Data as Foundation: Requires structured ingestion of manufacturing data streams.

- Algorithmic Learning: Models learn relationships from data without explicit programming for every scenario.

- Adaptive Capability: Systems can improve performance over time with new data.

- Integration Need: Must interface with existing production line hardware and software.

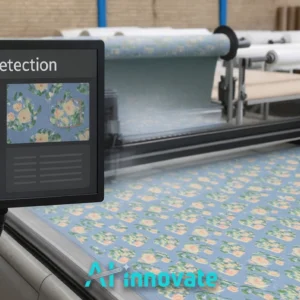

Visual Inspection Automation with AI

One of the most tangible and immediately impactful applications of AI in quality management is the automation of visual inspection processes. Manual visual inspection, though essential, is inherently prone to human fatigue, subjective judgment, and inconsistency, severely limiting the thoroughness and speed of defect detection in manufacturing.

This crucial function is being transformed by sophisticated detection. AI-powered machine vision systems function by:

- Capturing high-speed, high-resolution visual data streams from products moving along the production line.

- Employing algorithms to analyze the imagery, looking for deviations from predefined acceptable standards or identifying known defect patterns.

- Performing this analysis continuously on 100% of the product output, enabling real-time defect analysis.

Specific technical considerations include:

Image Acquisition Rigor

Ensuring consistent lighting, camera angles, and focus across every item inspected is critical. The quality of the input imagery directly affects the performance of the AI model. Industrial-grade cameras providing necessary resolution and capture speed are fundamental hardware components.

Model Training with Diverse Datasets

Training robust AI models to recognize defects requires extensive, accurately labeled datasets covering all variations of acceptable products and a wide range of defect types, presented under varying conditions.

Output Integration

The system must seamlessly integrate with production line control systems to trigger actions based on detection, such as diverting defective items for further analysis or scrap.

The precision of these systems is significant, extending beyond macroscopic flaws to microscopic details necessary for meticulous inspections. AI-Innovate’s AI2Eye system is built on these advanced principles, providing manufacturing lines with sophisticated visual intelligence capable of highly accurate, real-time, on-line defect detection across diverse industrial materials and production environments.

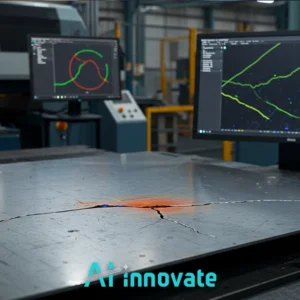

Predictive Insights for Process Excellence

Beyond identifying defects that have already occurred, AI empowers manufacturers to intervene earlier by anticipating potential quality issues upstream within the production workflow.

This capability shifts the paradigm from reactive quality control to proactive prevention. By continuously collecting and analyzing streams of operational data generated by various production assets—including process parameters from machinery, environmental sensor data, and historical process outcomes—AI models can uncover subtle interdependencies and drift points that serve as indicators for future quality deviations.

This relies on the application of machine learning for manufacturing process optimization and advanced analytics to:

- Identify abnormal patterns in process parameters that precede defect generation.

- Correlate combinations of operational conditions with known types of defects.

- Build predictive models capable of estimating the probability of defects occurring based on the real-time state of multiple process variables.

These predictive capabilities enable operations teams to receive alerts prompting adjustments to machine settings or process variables before defective products are produced. This supports more precise industrial process control, leading to a more stable and consistent production output, reducing variance and ultimately minimizing defect creation at its source.

Systems incorporating these analytical engines, akin to features found within AI2Eye, leverage these continuous data streams to offer data-driven recommendations for optimizing process parameters, contributing directly to enhanced manufacturing efficiency and product quality by reducing the inherent causes of defects.

The ROI of AI Quality Implementations

For industrial leadership assessing the viability and strategic advantage of adopting AI-Driven quality control, demonstrating a clear and favorable return on investment (ROI) is paramount.

The financial and operational benefits generated by integrating AI into quality processes are substantial and quantifiable, directly contributing to the bottom line and strengthening competitive position. Key quantifiable benefits driving ROI include:

- Maximized Throughput and Efficiency: Automated, high-speed inspection allows production lines to operate at optimal speeds without creating a quality bottleneck, increasing overall output capacity.

- Significant Waste Reduction: Early detection of defects, particularly through predictive capabilities and 100% inspection, prevents non-conforming products from proceeding down the line or being created at all, leading to less scrap material and reduced rework costs.

- Lower Operational Costs: Reduced material waste, diminished need for extensive manual quality checks, optimized energy consumption through fine-tuned processes, and decreased expenses related to customer returns and warranty claims contribute to substantial cost savings.

- Improved Product Consistency: AI’s objective and tireless inspection capability ensures a consistently high standard of product quality, enhancing customer satisfaction, fostering brand loyalty, and reducing the risk of reputational damage associated with quality lapses.

- Data-Informed Continuous Improvement: The rich datasets and insights generated by AI QC systems provide valuable information for root cause analysis and process refinement, supporting ongoing initiatives to further optimize operations and quality standards.

Accelerating Machine Vision Development

Development teams building advanced machine vision systems for AI-Driven Quality Control encounter key hurdles in traditional workflows, primarily dependence on physical camera hardware.

Acquiring diverse hardware to accurately replicate varied industrial conditions for machine learning in quality control model testing is time-consuming and costly. Creating extensive, annotated datasets for defect variations under multiple conditions also requires significant effort or complex real-world setups.

These challenges inherently slow the vital iterative process of model training, testing, and refinement essential for accurate defect detection applications. Overcoming these dependencies is critical for innovation.

Recognizing these developmental friction points for AI and vision engineers, AI-Innovate engineered AI2Cam. This cutting-edge software is designed to significantly streamline this workflow.

AI2Cam functions as a powerful Camera Emulator, letting developers test and refine their machine vision algorithms and models by simulating parameters and image conditions entirely in a flexible software environment, decoupling the process from physical hardware limits. Benefits of leveraging a tool like AI2Cam for machine vision development include:

- Lower Hardware Costs: Eliminates the need to purchase and maintain a large collection of physical test cameras solely for development and testing purposes.

- Faster Iteration: Enables rapid simulation of numerous scenarios that would be impractical or prohibitively time-consuming to set up physically.

- Enhanced Flexibility: Provides the ability to easily generate specific training data subsets covering rare defects or challenging environmental conditions.

- Improved Collaboration: Facilitates easier collaboration among geographically dispersed development teams working on the same models.

By abstracting away physical camera dependencies and simplifying dataset generation under controlled virtual conditions, AI2Cam empowers technical teams to accelerate their innovation pipeline, bringing more accurate and robust AI-Driven Quality Control solutions to market or deployment faster and more efficiently.

Ethical Considerations and Bias in AI Quality Control

While the benefits of AI-Driven Quality Control are compelling, its deployment also introduces critical ethical considerations that manufacturers must address to ensure responsible and trustworthy operation. These concerns, though often overlooked, have direct implications for accuracy, fairness, and compliance.

Key ethical considerations include:

- Bias in Training Data: AI models are only as good as the data they learn from. If certain defect types, materials, or production conditions are underrepresented in the dataset, the model’s performance may become inconsistent or skewed. To ensure fair and reliable defect detection, it’s essential to include diverse and representative data during training.

- Transparency and Explainability: The decision-making processes of AI models must be interpretable, especially in industries governed by strict compliance requirements. Manufacturers adopting AI-Driven Quality Control should implement models and workflows that can clearly articulate how and why inspection decisions are made.

- Human Oversight: While AI can handle many tasks autonomously, excluding human input entirely can be risky, especially in borderline or uncertain cases. Maintaining human-in-the-loop processes allows trained operators to intervene when needed, adding a layer of accountability.

- Ethical Risk of Overreliance: Placing too much trust in automation without proper validation can propagate errors at scale. Routine audits, performance monitoring, and regular model retraining help mitigate this risk.

As AI-Driven Quality Control becomes increasingly integral to modern manufacturing, addressing these ethical dimensions proactively ensures not only technical success but also long-term trust and operational integrity.

Navigating the Adoption Landscape

Successfully integrating AI-Driven Quality Control into an existing manufacturing infrastructure is a strategic undertaking that involves addressing several practical considerations and potential challenges.

While the transformative benefits are clear, a pragmatic approach is necessary to ensure seamless implementation and sustained operational effectiveness. Key areas demanding careful planning during adoption:

- Data Strategy and Readiness: Establishing robust processes for the collection, storage, labeling, and management of the high-quality data essential for training and validating AI models. Ensuring data consistency across production lines and over time is crucial.

- Technology Integration: Planning for the seamless integration of new AI software platforms and potentially dedicated processing hardware or smart cameras with existing manufacturing execution systems (MES), supervisory control and data acquisition (SCADA) systems, and other legacy infrastructure. This often involves navigating diverse communication protocols and data formats.

- Workforce Training and Skilling: Preparing production line personnel, maintenance teams, and engineering staff to effectively interact with AI-powered systems. This includes training on monitoring system performance, basic troubleshooting, interpreting AI-generated insights, and adapting workflows.

- Validation and Performance Monitoring: Developing protocols for rigorous validation of AI model accuracy in the specific production environment before full deployment, and establishing ongoing monitoring mechanisms to ensure sustained performance over time and identify potential drift.

- Cybersecurity Implementation: Implementing robust cybersecurity measures tailored for industrial AI systems to protect sensitive production data and operational control networks from unauthorized access or cyber threats, which is paramount given increased connectivity.

Successfully navigating these multifaceted challenges requires a clear roadmap, deep technical understanding, and effective collaboration across IT, operations, and quality departments. Partnering with organizations experienced in implementing AI within industrial settings can significantly mitigate risks and accelerate time-to-value. Navigating these complexities requires expertise.

At AI-Innovate, we specialize in partnering with manufacturers, leveraging our deep knowledge and proven solutions to streamline the adoption of AI-Driven Quality Control systems tailored to their unique operational landscapes and technical challenges, ensuring a smoother transition and maximized operational benefit from their AI investment.

Conclusion

The implementation of AI-Driven Quality Control marks a significant leap for manufacturing quality assurance. Leveraging advancements in machine learning and computer vision transforms processes, enabling unprecedented defect detection precision and predictive insights. Overcoming implementation challenges requires careful planning and expert guidance. Elevate your manufacturing quality standards with advanced AI solutions. Explore intelligent, practical AI QC capabilities offered by AI-Innovate for enhancing performance and achieving manufacturing excellence.