Industrial environments operate under constant pressure to enhance efficiency and maintain quality against complex, dynamic variables. Traditional control systems, while reliable for simple tasks, lack the foresight to manage modern manufacturing’s intricacies, creating a clear demand for superior solutions. This is where the power of AI for Industrial Process Control emerges as a transformative force.

At AI-Innovate, we specialize in developing the software that embeds this intelligence into workflows. This article provides a technical exploration of how these algorithms are reshaping control, moving beyond reactive adjustments to achieve predictive governance and tangible results.

Smarter Control , Higher Output

Let AI run the rules so you can run the results.

Beyond Reactive Control Loops

For decades, the backbone of industrial automation has been the Proportional-Integral-Derivative (PID) controller. Its logic is fundamentally reactive; it measures a process variable, compares it to a desired setpoint, and corrects for the detected error.

While effective for stable, linear systems, this after-the-fact approach struggles with the realities of modern production: significant process latency, complex non-linear behaviors, and the subtle interdependencies between multiple variables.

This results in overshoots, oscillations, and an inability to proactively counter disturbances, leading directly to inconsistent product quality and inefficient resource consumption. The limitations of this paradigm reveal the clear need for more advanced solutions in the field of AI for Industrial Process Control.

The contrast between these legacy systems and a modern, predictive approach is stark, as the following comparison illustrates:

| Metric | Reactive Control (e.g., PID) | Predictive Control (e.g., MPC/AI) |

| Response Basis | Corrects current, existing errors | Predicts future states and acts preemptively |

| Complexity Handling | Struggles with multiple, interacting variables | Models and optimizes for complex interdependencies |

| Goal | Maintain a single setpoint | Achieve an optimal outcome (e.g., max yield) |

Algorithmic Process Governance

The conceptual leap forward lies in shifting from static rule-based control to dynamic, algorithmic governance. This paradigm uses learning models to continuously define and execute optimal operational policies, effectively entrusting the system’s “wisdom” to algorithms that adapt in real-time.

Rather than relying on fixed human-defined setpoints, these systems can analyze vast streams of historical and live sensor data to determine the most effective operating recipe for any given circumstance.

This is the essence of true machine learning for manufacturing process optimization, where process control evolves into a self-tuning, intelligent function. This advanced governance operates on two fundamental principles that drive its effectiveness:

Data-Driven Policy Making

Models analyze production data to identify subtle patterns that correlate specific control actions with desired outcomes, such as improved yield or reduced energy consumption. The system codifies these findings into an evolving set of control policies, effectively learning from its own operational history.

Dynamic Adaptation Models

These models are designed to adjust their internal parameters as conditions change. Whether it’s a shift in raw material quality or environmental factors, the system dynamically adapts its control strategy to maintain optimal performance, mitigating deviations before they escalate.

Mastering In-Line Anomaly Detection

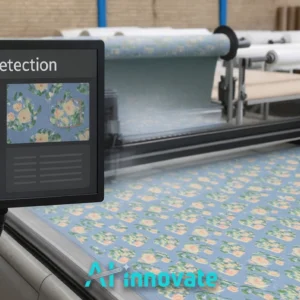

One of the most immediate and high-impact applications of this intelligence is in automated quality assurance. Traditional quality control often relies on manual inspection or post-production sampling, methods that are slow, prone to human error, and costly.

By embedding intelligence directly on the production line, AI-driven quality control transforms this function from a bottleneck into a competitive advantage. This approach allows for the immediate identification of minute imperfections that are virtually invisible to the human eye. The impact of such real-time defect analysis on the bottom line is direct and substantial.

For manufacturers in sectors like textiles, metals, or polymers, implementing this capability is no longer a futuristic concept. Specialized solutions like AI-Innovate’s AI2Eye are engineered to integrate seamlessly into existing lines, providing a vigilant, automated inspection system. The tangible benefits directly address critical operational KPIs, a few of which include:

- Drastic reduction in scrap material and rework costs by catching flaws at their point of origin.

- Enhanced product consistency and quality, securing brand reputation and customer trust.

- Increased throughput by eliminating the need for manual inspection stops and starts.

Accelerating Development via Emulation

For the technical teams tasked with creating these advanced systems, the development lifecycle presents its own set of challenges. Prototyping and testing machine vision for defect detection models have historically been constrained by a dependency on physical camera hardware, which is often expensive, inflexible, and creates significant project delays.

This hardware-centric approach slows down innovation and limits the scope of testing. The strategic answer to this bottleneck is emulation. This software-first methodology, which allows developers to test applications using a “virtual camera,” is central to modern AI for Industrial Process Control.

The immediate shift to an emulated environment unlocks several powerful advantages for development teams. Let’s explore a few key benefits:

- It decouples software development from hardware procurement, allowing parallel workstreams and faster-time-to-market.

- It slashes prototyping costs by removing the need to purchase and maintain expensive and diverse camera equipment.

- It enables rapid, flexible testing across a vast range of simulated conditions and camera models that would be impractical to set up physically.

- It fosters seamless remote collaboration, as teams can share and work on projects without shipping physical hardware.

By providing a robust virtual environment, tools like AI-Innovate’s AI2Cam camera emulator empower engineers and R&D specialists to build, test, and refine their vision applications with unprecedented speed and agility.

The Data Fidelity Imperative

Let us be clear: no algorithm, regardless of its sophistication, can deliver meaningful results from flawed data. The success of any intelligent system is anchored entirely in the quality and integrity of the data it consumes.

This principle of “Garbage In, Garbage Out” is not just a catchphrase; it is a fundamental law in this domain. Factors like sensor drift, improper calibration, and environmental noise can introduce inaccuracies that mislead even the most advanced models, leading to poor decision-making and eroding trust in the system.

Therefore, a rigorous commitment to data fidelity is a non-negotiable prerequisite for successful implementation. The value derived from AI for Industrial Process Control is directly proportional to the quality of its underlying data foundation.

The most sophisticated algorithm cannot compensate for poor calibration and noisy data. True industrial intelligence begins not with the model, but with the measurement.

Bridging Simulation and Reality

The most effective development and deployment strategy creates a powerful synergy between the virtual and physical worlds. The workflow is no longer linear and rigid but cyclical and iterative, leveraging the strengths of both simulation and real-world application.

This integrated approach ensures that models are not only theoretically sound but also practically robust and ready for the complexities of the factory floor. This is how cutting-edge tools are successfully operationalized in the complex domain of industrial automation.

This modern workflow, which bridges the gap from concept to deployment, follows a clear and structured pathway, a summary of which you can see here:

- Virtual Prototyping & Development: Engineers use emulators like AI2Cam to build and rigorously test machine vision models against thousands of simulated scenarios, refining algorithms without the need for a single piece of physical hardware.

- Confident Model Validation: Once validated in the virtual environment, the model’s logic is proven. The development team has high confidence that the software will perform as expected when deployed.

- Seamless On-Site Deployment: The validated model is then deployed onto real-world hardware, such as the AI2Eye system, to begin its work on the actual production line. The transition is seamless because the software has already been hardened. This holistic lifecycle is a hallmark of modern AI for Industrial Process Control.

Quantifying Operational Gains

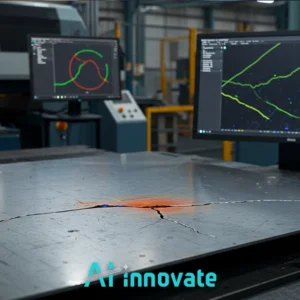

Ultimately, the adoption of advanced technology in a production environment must be justified by measurable improvements in key performance indicators (KPIs). For operations directors and QA managers, the value of this technology is not found in its novelty but in its proven ability to deliver a clear return on investment.

The application of AI for Industrial Process Control delivers tangible operational advantages that directly impact efficiency, cost, and quality across the value chain.

The impact of this technology is not theoretical; it is measured against the bottom line. Let’s examine some core areas of transformation, particularly focusing on the crucial task of Defect Detection in Manufacturing.

| Area of Impact | Traditional Challenge | AI-Driven Improvement |

| Scrap & Rework | High costs due to late detection of flaws | Immediate, in-line detection minimizes material waste |

| Labor Efficiency | Manual inspection is slow and error-prone | Frees skilled staff for higher-value analysis tasks |

| Process Stability | Inconsistent output from undetected anomalies | Real-time feedback enables rapid process correction |

Conclusion

The transition from reactive to predictive process control represents a fundamental evolution in manufacturing. By embracing algorithmic governance, mastering in-line anomaly detection, and leveraging emulation for rapid development, industries can unlock unprecedented levels of efficiency and quality. This journey, however, hinges on a steadfast commitment to data fidelity and a clear understanding of how to quantify operational gains. For organizations ready to make this transformation, partnering with a specialist like AI-Innovate provides the expertise needed to turn technological potential into tangible, real-world results.