The new benchmark for operational excellence is being set by factories that can see, analyze, and act with intelligent automation. This capability is rapidly becoming the primary differentiator between market leaders and their competitors.

AI-Innovate equips industrial pioneers with the perceptual intelligence required to not just compete, but to dominate their respective sectors. This document provides a forward-looking analysis of the essential computer vision applications shaping the future of manufacturing, offering a blueprint for organizations aiming to build a decisive and lasting competitive advantage through technological leadership.

Unlock the Power of ML in Industry 4.0

Leverage cutting-edge machine learning to automate, optimize, and scale your smart factory today.

From Pixels to Production Insights

The fundamental process of turning raw visual data into strategic industrial intelligence is a structured and elegant workflow. It begins not with complex algorithms, but with the simple capture of an image, which is merely a collection of pixels.

However, it’s the intelligent processing of these pixels that unlocks immense value, allowing systems to understand and react to the physical world with precision. For any industrial leader or technical specialist, grasping this core sequence is the first step toward appreciating its power. The entire journey from a camera lens to a command on the factory floor can be distilled into four key stages:

- Image Acquisition: High-resolution industrial cameras and sensors capture visual data from the product or environment. This is the system’s “eyesight.”

- Data Pre-processing: The raw image is cleaned, normalized, and optimized. This step removes noise, corrects lighting variations, and enhances features to prepare the data for analysis.

- AI Analysis: Deep learning models, primarily Convolutional Neural Networks (CNNs), analyze the prepared data to identify patterns, objects, or anomalies based on their training. This is the cognitive “brain” of the system.

- Actionable Decision: Based on the analysis, the system triggers an action—such as diverting a faulty product, alerting an operator, or guiding a robotic arm.

Zero-Defect Manufacturing Vision

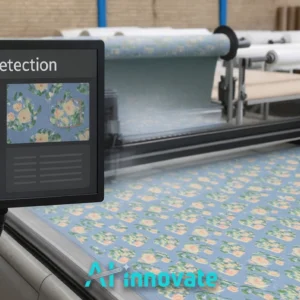

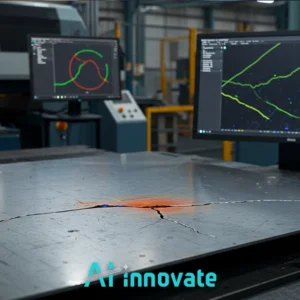

Perhaps the most impactful application of machine vision lies in the pursuit of zero-defect manufacturing. Human inspection, while valuable, is inherently limited by factors like fatigue, inconsistency, and the sheer speed of modern production lines.

Automated quality control systems overcome these barriers by providing tireless, high-precision inspection, 24/7. This technology is a direct answer to the challenges faced by Quality Assurance Managers, offering a clear and rapid return on investment by drastically reducing scrap rates and preventing flawed products from ever reaching the customer.

An automated vision system is capable of detecting a vast array of imperfections, many of which are impossible to spot with the naked eye. Key examples include:

- Microscopic Surface Flaws: Tiny cracks, scratches, dents, or pinholes in materials like metal, polymer, or glass.

- Color and Texture Inconsistencies: Subtle variations in color, finish, or material texture that indicate a process error.

- Assembly and Alignment Errors: Verifying that all components are present, correctly oriented, and assembled within specified tolerances.

- Printing and Labeling Defects: Ensuring barcodes are readable, text is accurate, and labels are correctly positioned on packaging.

Read Also: Machine Vision for Defect Detection – Boost Product Quality

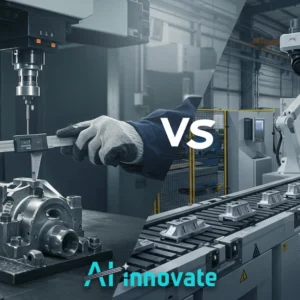

Automated Robotic Precision

In modern industrial settings, robots are the workforce, but computer vision provides the critical sense of sight that enables true autonomy and precision. Without it, a robot is limited to performing pre-programmed, repetitive motions.

With vision guidance, a robot can adapt to variability in its environment, handling tasks that require precision and flexibility. This synergy between robotics and vision is fundamental to automating complex assembly lines, especially in the automotive and electronics sectors.

For Operations Directors, this integration means higher throughput, improved product quality, and the ability to automate tasks previously deemed too intricate for machines. The value of this technology becomes even clearer when we consider how a machine “sees” and adapts to its work.

Such advancements form a core component of the wider landscape of Computer Vision Applications in Industry. The difference in capability is stark when compared directly:

| Feature | Traditional Robotics | Vision-Guided Robotics |

| Component Handling | Requires fixed part presentation | Adapts to varying part locations |

| Task Flexibility | Limited to one repetitive task | Can switch between tasks easily |

| Precision Level | High, but only in static setups | Extreme precision in dynamic environments |

| Error Correction | Cannot adapt to unexpected events | Identifies and adjusts for errors in real-time |

Supply Chain Visual Intelligence

The utility of computer vision extends far beyond the four walls of the factory floor, revolutionizing logistics and supply chain management. In massive warehouses and distribution centers, visual intelligence systems provide a level of accuracy and efficiency that manual tracking methods cannot match.

Autonomous drones equipped with cameras can perform rapid inventory cycles, scanning barcodes and QR codes from the air without human intervention. Similarly, vision-guided robots can navigate complex warehouse environments to sort, pick, and transport goods, drastically accelerating order fulfillment times and reducing labor costs.

This application delivers continuous, data-driven insights to operations leaders, optimizing stock levels, minimizing search times, and creating a more transparent and responsive supply chain. The tangible impact of these Computer Vision Applications in Industry is evident in the world’s most advanced logistics operations.

Case Study Snippet: The Amazon Model

In its fulfillment centers, Amazon deploys thousands of autonomous robots and vision systems. These technologies are not just supplemental; they are integral to the operation, enabling the company to process millions of orders daily with unparalleled speed and accuracy. The system tracks every item from arrival to dispatch, optimizing storage and retrieval routes in real time.

Proactive Workplace Safety Systems

Beyond production and efficiency, computer vision serves a vital human-centric role: creating safer industrial environments. These systems act as a vigilant, unblinking observer, capable of identifying and flagging potential hazards before they lead to accidents.

By continuously monitoring the workplace, AI-powered cameras can ensure compliance with critical safety protocols, providing a new layer of protection for employees. This addresses a core responsibility for all industrial leaders, as it reduces the risk of injury, minimizes liability, and fosters a culture of safety.

The proactive nature of these systems allows for immediate intervention when a risk is detected, a significant improvement over reactive post-accident analysis. Common scenarios where these systems are deployed include:

- Personal Protective Equipment (PPE) Detection: Automatically verifying that all personnel in a designated zone are wearing required gear such as hard hats, safety glasses, or high-visibility vests.

- Hazardous Zone Monitoring: Triggering an alert if a person or vehicle enters a restricted or dangerous area, such as the operational envelope of a heavy robot.

- Ergonomic and Fatigue Analysis: Identifying worker postures or movement patterns that could lead to long-term strain injuries or detecting signs of fatigue to prevent accidents.

- Spill and Obstruction Detection: Recognizing fluid spills or misplaced objects on the floor that pose a slip-and-fall risk.

Bridging Simulation and Reality

For the Technical Developers, ML Engineers, and R&D Specialists driving innovation, one of the most significant bottlenecks is the dependency on physical hardware for development and testing. Acquiring, setting up, and maintaining a diverse range of industrial cameras and lighting conditions is both costly and time-consuming, leading to project delays.

This physical constraint often limits the scope of testing and stifles rapid prototyping. The solution is to decouple software development from physical hardware. This is achieved with sophisticated camera emulators, a type of software that acts as a virtual camera.

These tools allow developers to simulate an entire range of industrial cameras, sensors, and environmental conditions directly from their computers. By working in a virtual environment, development cycles are dramatically accelerated.

To meet this specific need, our powerful software tool, AI2Cam, provides this exact functionality. It offers a virtual camera environment designed to give developers the ultimate flexibility to innovate, enabling:

- Faster Prototyping: Test code and ideas instantly without waiting for hardware setups.

- Significant Cost Reduction: Eliminate the expense of purchasing and maintaining physical cameras for testing.

- Enhanced Flexibility: Simulate countless scenarios—from different lighting to various camera models—that are impractical to create physically.

- Seamless Remote Collaboration: Allow teams across the globe to work on the same project without shipping equipment.

The Strategic Implementation Roadmap

For industrial leaders, successful adoption of computer vision isn’t about buying technology—it’s about strategic execution. A disciplined roadmap is essential to target the right problems, avoid costly missteps, and ensure a transparent return on investment (ROI).

This approach aligns the solution with core business goals, making the real-world Computer Vision Applications in Industry both effective and accessible. We recommend these four key steps for a successful deployment:

- Identify the Core Bottleneck: Analyze your production line to pinpoint the single issue (e.g., defects, speed, inventory) where improvement will deliver the greatest financial impact.

- Gather Foundational Data: Collect a robust dataset of images and videos from the target area. This data must include clear examples of both normal operations and the specific problems you aim to solve.

- Select the Right Solution: Choose a tool engineered for your specific challenge. For real-time quality control, a purpose-built system like our AI2Eye integrates seamlessly into production lines, offering immediate defect detection and process analytics to deliver a clear ROI.

- Measure and Validate Performance: Launch a pilot project and track key metrics (e.g., defect rates, throughput, waste reduction) against your benchmarks. This validates the ROI before you commit to a full-scale deployment.

Conclusion

Computer vision is no longer a technology of the future; it is a present-day industrial reality, creating factories that are smarter, safer, and more efficient. From guaranteeing product quality with superhuman precision to guiding robots and protecting workers, its applications are both diverse and transformative.

For industrial leaders, it offers a direct path to higher quality and lower costs. For technical developers, it opens a new frontier of innovation. By embracing practical, purpose-built tools, companies can effectively implement Computer Vision Applications in Industry. AI-Innovate is committed to being your dedicated partner in this journey, transforming industrial challenges into intelligent solutions.