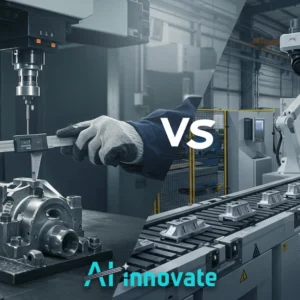

The era of relying solely on manual quality control in metalworking is rapidly drawing to a close. As production lines accelerate and component tolerances tighten, the natural limitations of human perception become a critical industrial liability. The sector is now turning to intelligent automation to achieve a new threshold of speed and reliability.

AI-Innovate stands at the forefront of this essential transition, developing the sophisticated software that powers this next generation of industrial inspection. In this analysis, we explore the core mechanics of Computer Vision in Metal Quality Control, detailing the advanced imaging techniques and deep learning models that ensure its success.

Upgrade Your Quality Control with Machine Learning

From data to decisions – let ML handle the complexity.

The Digital Scrutiny of Surfaces

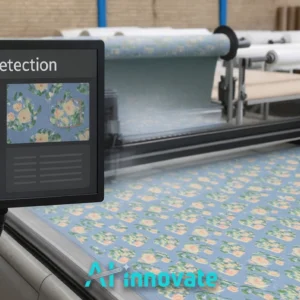

The power of modern automated inspection lies in its ability to perceive and interpret surfaces with superhuman accuracy. Unlike traditional machine vision, which typically checks for a single, predefined flaw, contemporary systems leverage deep learning.

This allows for the simultaneous detection and classification of a wide array of defects—such as cracks, scratches, and pitting—with remarkable granularity. This sophisticated analysis unfolds through a structured, multi-stage process which forms the bedrock of effective Computer Vision in Metal Quality Control. Let’s examine these critical steps.

- Image Acquisition: High-resolution industrial cameras and sensors capture raw visual data from the metal surface under specific lighting conditions to maximize defect visibility.

- Pre-processing: The raw image is refined. Algorithms work to remove noise, normalize lighting inconsistencies, and enhance the contrast between the flawless surface and potential imperfections. This step is crucial for reliable analysis.

- Feature Extraction: The system intelligently identifies key visual characteristics (features) that define a defect, learning the unique signatures of different types of flaws.

- Defect Classification: Finally, a trained AI model classifies the identified features, not only confirming the presence of a defect but also categorizing it by type and severity, providing actionable data for process improvement.

Read Also: Metal Defect Detection – Smart Systems for Zero Defects

Imaging Techniques for Flaw Detection

A system’s analytical power is only as good as the data it receives. The choice of imaging technology is therefore fundamental to detecting specific types of flaws, especially those invisible to standard cameras.

To achieve a comprehensive inspection, a combination of advanced imaging techniques is often employed. Below, we explore a few of the most impactful methods used today.

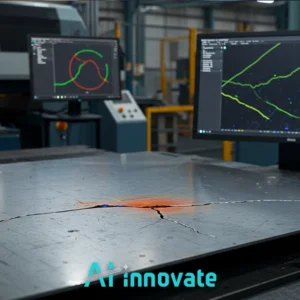

Thermographic Imaging

This technique uses thermal cameras to detect minute temperature variations on a metal’s surface. Flaws like subsurface cracks, delamination, or inconsistencies in material density can alter heat distribution. Thermography reveals these thermal anomalies, pointing to structural defects that would otherwise go unnoticed until a potential failure.

3D Laser Scanning

For applications demanding exceptional precision, 3D laser scanners map the exact topography of a metal surface. By creating a detailed three-dimensional point cloud, these systems can identify and measure geometric imperfections like dents, warping, or scratches with micrometer-level accuracy. This is essential for high-tolerance components where even the slightest deviation is unacceptable.

X-Ray Imaging

Certain critical flaws, such as porosity or cracks within welds, are internal to the material. X-ray imaging provides a non-destructive way to see inside the metal part. By passing radiation through the component and capturing the resulting image, inspectors can identify hidden voids and internal structural weaknesses that compromise the product’s integrity.

Operational Gains Through Automation

Adopting automation is not merely a technical upgrade; it is a strategic business decision that delivers quantifiable returns. By replacing manual inspection with intelligent systems, industrial leaders can unlock significant and measurable improvements across the factory floor.

The impact spans from cost reduction to enhanced safety and productivity. The data gathered from early adopters presents a clear picture of these advantages, and the demonstrated ROI for Computer Vision in Metal Quality Control is a compelling driver for adoption.

Our own solutions have demonstrated the ability to improve operational efficiency by up to 30% and reduce production downtime by as much as 40%. The table below summarizes some of the key gains reported across the industry.

| Area of Improvement | Measured Impact |

| Inspection Time Reduction | Over 60% in aluminum alloy processing |

| Operational Efficiency | Up to 30% improvement |

| Production Downtime | Up to 40% decrease |

| Worker Safety | Enhanced through automated hot-spot detection |

Implementation Hurdles and Costs

To build trust, it is essential to be transparent about the challenges of implementation. Adopting an automated inspection system is a significant project that comes with practical considerations. A primary factor is the initial investment. The hardware and software for a robust system can range from $10,000 to $50,000, with a typical implementation timeline of four to six weeks. This initial outlay requires careful planning and budgeting.

A more technical challenge is the acquisition of training data. AI models, particularly those based on deep learning, require a large and diverse dataset of labeled images to learn accurately. For many companies, compiling and annotating thousands of images representing every possible defect is a substantial, time-consuming task. This “data hurdle” is often one of the biggest practical obstacles to overcome when developing a system from the ground up.

A Practical Path to Automated Inspection

While these challenges are real, our solutions are designed to directly overcome them. We provide a practical, streamlined path to adopting advanced quality control, tailored to the distinct needs of both industrial managers and technical developers.

For Industrial Leaders: AI2Eye

AI2Eye turnkey system offers real-time inspection and process optimization without the long development cycle.

- Detects surface defects on the live production line.

- Analyzes process data to identify and resolve inefficiencies.

- Reduces material waste and improves overall product quality.

For Technical Developers: AI2Cam

AI2Cam powerful camera emulator accelerates the development of vision applications by removing hardware dependencies.

- Simulate any industrial camera to prototype ideas instantly.

- Eliminate the costs of purchasing and maintaining test hardware.

- Collaborate remotely with teams without sharing physical equipment.

Frontiers in Quality Control AI

Staying competitive requires an understanding of where the technology is headed. The landscape of Computer Vision in Metal Quality Control is evolving rapidly, driven by innovations that make the technology more accessible, flexible, and powerful. We are actively engaged with several key frontiers poised to reshape the industry.

- Cloud-Based AI Platforms: Emerging platforms are democratizing access to powerful AI. Companies can leverage cloud infrastructure for model training and deployment without needing extensive in-house expertise, significantly lowering the barrier to entry.

- CAD-Driven Inspection: New systems are being developed that use a component’s original CAD design as the baseline for inspection. This groundbreaking approach eliminates the need for training on thousands of defect images, enabling accurate quality control from the very first unit produced.

- Generative AI for Synthetic Data: To solve the data bottleneck, companies are turning to generative AI. This technology can create vast, realistic datasets of synthetic defect images, enabling the training of highly accurate models without the time and expense of collecting real-world examples.

Read Also: AI-Driven Quality Control – Transforming QC With AI

Conclusion

The evidence is clear: the integration of automated inspection is a strategic imperative. It addresses the core industrial challenges of cost, quality, and efficiency with a level of precision and consistency that is unattainable through manual methods. For leaders in the metal industry, adopting Computer Vision in Metal Quality Control is no longer a distant possibility but a crucial step toward building a resilient, competitive, and intelligent manufacturing future.