In modern manufacturing, achieving flawless product quality is paramount. For industries like textiles, the challenge of implementing effective Fabric Defect Detection across vast production runs has traditionally been met with inconsistent human sight. As industries pivot to smarter systems, the very methodology of quality control is being reimagined.

AI-Innovate spearheads this transformation, offering intelligent tools for these critical industrial challenges. This article delves into the technical evolution of automated inspection, from its statistical roots to the powerful deep learning systems that define modern industrial excellence such as fabric defect detection using image processing.

Flawless Fabric Starts with Smart Detection

AI spots fabric defects invisible to the eye.

The Manual Inspection Fallacy

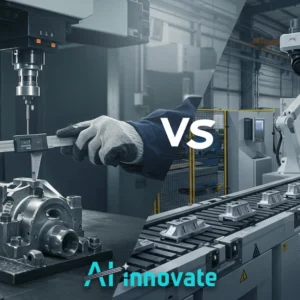

For decades, the standard for quality control was a line of human inspectors. This practice, however, is built on a fundamental fallacy: that the human eye can provide consistent, scalable, and cost-effective quality assurance. The data tells a different story.

Human inspectors typically achieve an accuracy of 60-75%, a figure that inevitably declines due to factors like fatigue and lapses in concentration. This leads to significant financial drain from undetected defects that result in scrap material and customer returns.

The process is not just error-prone; it’s a bottleneck. Halting production to record a defect, training new inspectors, and the sheer labor cost make it an unsustainable model in a competitive market.

Moving toward automated Fabric Defect Detection is not merely an upgrade; it’s a strategic necessity for any operation serious about implementing genuine AI for quality assurance. This transition addresses the core liabilities of manual oversight—cost, consistency, and efficiency—head-on.

Digital Image Acquisition Imperatives

The entire process of automated inspection begins with a single, critical step: capturing a high-fidelity digital image. The principle of ‘garbage in, garbage out’ is ruthlessly unforgiving here.

An effective machine vision for defect detection system is not built on software alone; it stands on a foundation of superior image acquisition hardware. The quality of this initial data dictates the performance ceiling for any subsequent analysis. Below are the key components that cannot be compromised.

- High-Resolution Sensors: Often utilizing line-scan cameras that capture the fabric as it moves, these sensors must possess the resolution to make the smallest defects, such as a broken thread, visible for analysis.

- Consistent Lighting: Non-uniform illumination is the primary source of error, creating shadows or bright spots that algorithms can misinterpret as defects. A controlled, even lighting environment is imperative to ensure the image reflects the true state of the fabric.

- Precise Optics: The lens system must provide a clear, distortion-free view of the fabric surface, ensuring that every part of the image is in sharp focus for the analytical algorithms.

Beyond the hardware, the initial software stage—image preprocessing—is equally vital. Raw images are rarely perfect. They contain noise from electronic sensors or minor variations in lighting that escaped physical control.

Applying techniques like Gaussian blurring to smooth out noise, histogram equalization to enhance contrast, or grayscale conversion to simplify the data is not a trivial step. It is the digital equivalent of cleaning and preparing a sample for analysis, ensuring that the core algorithms receive clean, consistent data to prevent false positives and missed defects.

Statistical and Spectral Foundations

Long before the advent of deep learning, engineers devised clever methods to automate inspection based on the inherent mathematical properties of textures. These foundational defect analysis Techniques provided the first real alternative to manual checks and can be broadly understood through two classical approaches.

Understanding these early methods is key to appreciating the sophistication of modern systems and represents the first logical steps in automated Fabric Defect Detection. Now, let’s look closer at these foundational techniques.

Statistical Approaches

These methods operate by quantifying the texture of a defect-free fabric. An algorithm like the Gray-Level Co-occurrence Matrix (GLCM), for instance, analyzes the spatial relationship between pixels.

It learns the “normal” pattern of how different gray tones appear next to each other. When a region of fabric deviates significantly from these learned statistical norms—perhaps due to a stain or a knot—it is flagged as a potential defect.

Spectral Approaches

Instead of analyzing spatial relationships, spectral methods transform the image into the frequency domain using tools like the Fourier or Wavelet Transform. Woven fabrics have a naturally periodic, repeating pattern. In the frequency domain, this regularity appears as distinct, sharp peaks.

A defect disrupts this periodicity, which manifests as a disturbance in the frequency spectrum, allowing the algorithm to detect anomalies that might be invisible to simple statistical analysis.

Evolving to Model-Based Heuristics

As the field matured, the next logical evolution was to move beyond analyzing general patterns toward creating explicit models of the perfect fabric. This marked a significant step forward in sophistication.

The core concept behind these model-based heuristics is elegantly simple: if you can build a perfect digital replica of a defect-free textile, you can use it as a reference to find imperfections. Any part of the real fabric image that cannot be accurately reconstructed by this “perfect” model is, by definition, a defect.

A prime example of this is Dictionary Learning, where the algorithm creates a “dictionary” of small, representative patches from flawless fabric samples. During inspection, the system attempts to build the new image using only pieces from its dictionary. Where it fails—where a patch is too foreign to be represented—a defect is located.

While these model-based systems represented a significant improvement, they still carried inherent limitations. Their performance was tightly bound to the specific type of fabric and defect they were designed for.

A model trained on plain-woven cotton would likely fail on a textured or patterned fabric. This lack of generality meant that new models had to be painstakingly engineered for each new product line.

The industry needed a more flexible, robust, and scalable approach—one that could learn and adapt without constant human re-engineering.

The Deep Learning Paradigm Shift

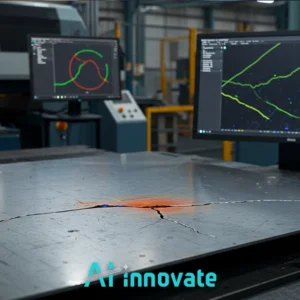

The arrival of deep learning, particularly Convolutional Neural Networks (CNNs), represents a genuine paradigm shift. All previous methods relied on human engineers to define the features of a defect—to tell the system what a “broken thread” or a “slub” looks like in mathematical terms.

Deep learning models eliminate this manual feature engineering. Instead, they learn these features autonomously from vast amounts of image data. Models like YOLO (You Only Look Once) are trained on thousands of examples of both good and bad fabric, learning to identify a vast array of defects with astonishing speed and accuracy.

This shift is crucial for handling complex fabric patterns and subtle defect types that baffled older algorithms, marking a new era for Fabric Defect Detection. Let’s examine the core differences in approach:

| Feature | Traditional Methods (Statistical, Spectral) | Deep Learning (CNN-based) |

| Feature Extraction | Manually engineered by experts | Learned automatically from data |

| Adaptability | Rigid; tuned for specific defect types | Highly adaptable; learns new defects from examples |

| Performance on Complex Patterns | Often struggles; high false alarm rate | Robust and highly accurate |

| Data Requirement | Relatively low | Requires large, labeled datasets |

However, the immense power of deep learning comes with a significant operational challenge: the need for large, high-quality, and meticulously labeled datasets. Acquiring and annotating thousands of images representing every possible defect under various conditions is a massive undertaking.

Data imbalance, where some defects are far more common than others, can also bias the model. Successfully implementing these advanced systems, therefore, relies not just on choosing the right network architecture, but on a strategic and robust data collection and management pipeline.

Real-Time Industrial Deployment

Translating these powerful algorithms from the lab to a high-speed production floor presents its own set of challenges. An academic model with 99% accuracy is useless if it takes ten seconds to process one meter of fabric on a line moving at sixty meters per minute.

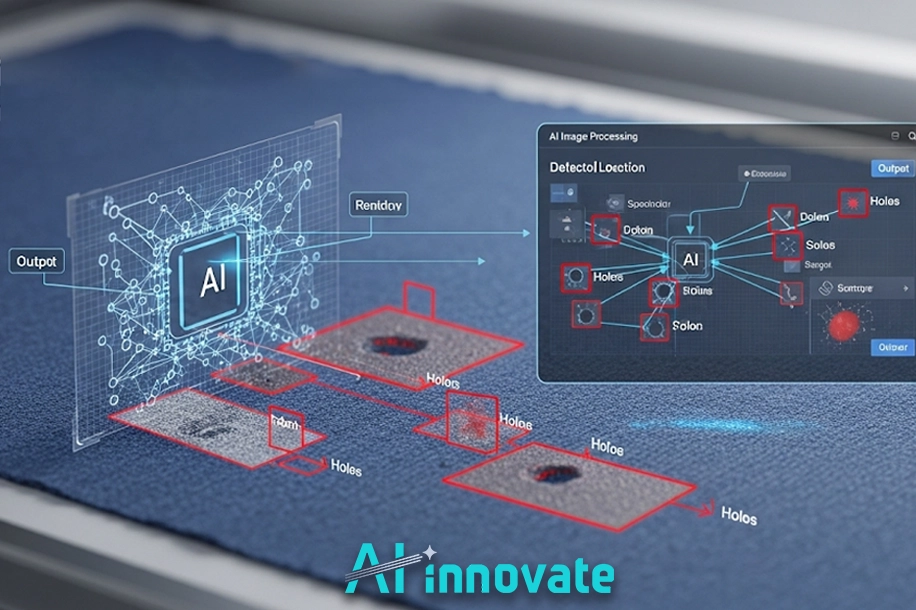

Effective industrial deployment requires real-time defect analysis and seamless integration into existing workflows. This is precisely the challenge AI-Innovate solves with AI2Eye. Designed for the factory floor, AI2Eye is not just a detection tool; it’s a complete process optimization engine.

It integrates directly into the production line, performing real-time Fabric Defect Detection without slowing down operations. More importantly, it provides data-driven insights to identify the root causes of recurring flaws, empowering QA Managers and Operations Directors to reduce waste, boost efficiency, and ensure a consistently higher standard of quality.

Accelerating Development with Emulation

For the R&D specialists and ML engineers building these next-generation systems, a major bottleneck is the dependency on physical hardware. Acquiring, setting up, and testing with a variety of industrial cameras is costly, time-consuming, and inflexible, severely hampering the pace of innovation.

This is where development tools that decouple software from hardware become invaluable. AI2Cam by AI-Innovate directly addresses this pain point. As a powerful camera emulator, AI2Cam allows developers to simulate a wide range of industrial cameras and imaging conditions directly on their computer.

This eliminates the need for expensive physical hardware during the prototyping and testing phases, drastically reducing costs and accelerating development cycles. Teams can experiment with new ideas, validate algorithms, and collaborate remotely with unprecedented flexibility, bringing innovation to market faster.

Conclusion

The journey from the subjective, error-prone practice of manual inspection to the precision of automated systems is a testament to technical ingenuity. We have progressed from foundational mathematical models to intelligent, self-learning algorithms that redefine AI-driven quality control. Today, effective Fabric Defect Detection is about more than just finding flaws; it’s a cornerstone of smart manufacturing. Adopting this technology is a strategic decision that drives efficiency, minimizes waste, and ultimately enhances product value for any modern industrial enterprise.