For industrial leaders, quality control is a direct driver of operational efficiency and profitability. Every undetected flaw represents potential waste, reduced throughput, and risk to customer satisfaction. The goal is a zero-defect process, and intelligent automation is the key to achieving it. At AI-Innovate, we engineer solutions that translate technological accuracy into measurable ROI.

This article bridges the gap between the technical and the strategic, exploring how advanced Metal Defect Detection not only identifies imperfections but also optimizes processes, empowering businesses to protect their bottom line and secure their competitive edge.

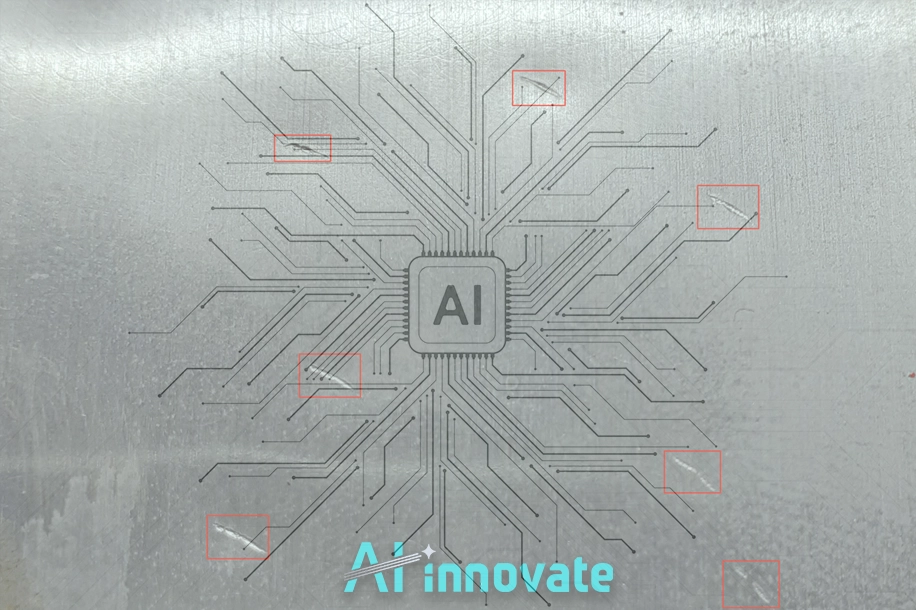

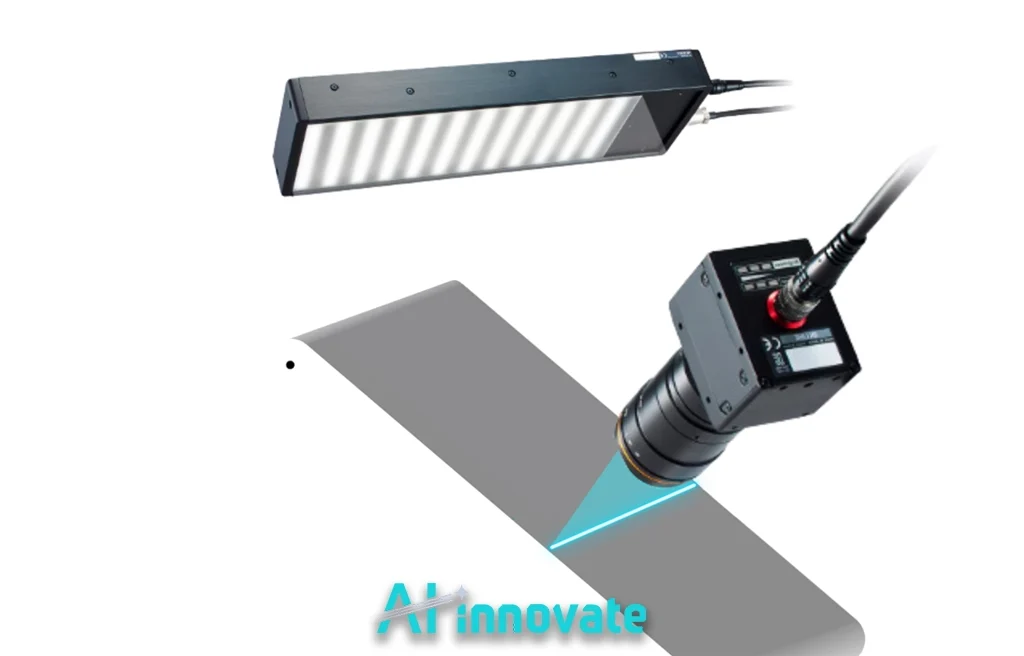

Catch Every Crack , & Deformation

High-speed detection of metal flaws in real-time.

The Material Integrity Mandate

The imperative for pristine metal surfaces goes far beyond aesthetics; it is a core tenet of modern engineering and risk management. A microscopic crack, inclusion, or scratch, seemingly insignificant on the production line, can become the nucleation point for catastrophic failure in the field.

In the automotive and aerospace sectors, such an oversight can have severe safety implications, leading to costly product recalls that damage both budgets and brand reputation. Therefore, material integrity is not merely a quality control checkpoint but a strategic imperative that directly impacts operational viability, safety, and market trust.

The Fallibility of Conventional Methods

Historically, the responsibility for identifying surface anomalies has fallen to human inspectors. This approach, while essential, is inherently prone to limitations such as fatigue, inconsistency, and subjective judgment, especially over long shifts.

The initial evolution towards automation introduced traditional machine vision for defect detection, which relied on pre-defined rules and thresholding. While an improvement, these systems are notoriously fragile;

they struggle to adapt to minor variations in lighting, surface texture, and reflectivity, often leading to a high rate of false positives or missed defects. Beyond manual checks, other traditional Non-Destructive Testing (NDT) methods like ultrasonic and eddy-current testing offer high precision, but primarily for sub-surface flaws.

For the high-speed, top-down inspection of surface quality on a production line, these methods are often too slow, costly, and complex to implement at scale. The initial wave of automated optical inspection (AOI) tried to solve this by using classic image processing.

While a step forward, these rule-based systems proved brittle, requiring constant, manual recalibration and failing to handle the slightest variations in real-world conditions. These legacy approaches are constrained by several fundamental weaknesses that we will explore further:

- Subjectivity and Inconsistency: Manual inspection results can vary significantly between inspectors and even for the same inspector over time.

- Scalability Issues: Both manual and early automated systems struggle to keep pace with high-speed production lines without compromising accuracy.

- Lack of Adaptability: Rule-based systems require extensive recalibration for new products or even minor changes in the manufacturing environment.

- Low Accuracy on Complex Defects: They often fail to reliably identify subtle, low-contrast, or geometrically intricate defects.

Semantic Interpretation of Surface Anomalies

The most significant leap in Metal Defect Detection technology is the shift from rudimentary pattern matching to semantic interpretation, powered by deep learning. Unlike traditional systems that see only a collection of pixels, modern neural networks learn the contextual meaning of an anomaly.

The system learns what constitutes a “scratch” in all its variations—straight, curved, deep, or faint—in the same way a human expert does. This ability to generalize from learned examples is the core differentiator, allowing the models to achieve robust performance amid the noise and variability of a real-world production environment.

Beyond Pattern Matching

This contextual understanding allows an AI-driven quality control system to distinguish between a benign surface texture variation and a critical flaw like crazing. Instead of relying on hand-crafted features engineered by a programmer, the model autonomously identifies the salient characteristics that define each defect class.

This approach results in a far more resilient and accurate inspection process, capable of handling a diverse range of materials and potential imperfections.

Benchmarking Detection Architectures

For technical developers and R&D specialists, selecting the right model architecture is a critical decision influenced by a trade-off between accuracy, speed, and computational cost. Recent academic benchmarks on datasets like Northeastern University (NEU) and GC10-DET provide invaluable insights into the performance of leading object detection models for this specific task.

These studies move the discussion from theoretical advantages to proven, empirical results, offering a clear view of the current state-of-the-art. This empirical evidence is crucial because it moves the discussion beyond theory and highlights a critical strategic decision for technical leaders.

There is no single “best” architecture; there is only the best fit for a specific operational context. The exceptional accuracy of a Deformable Convolutional Network (DCN) might be essential for a low-volume, critical safety component, whereas the unparalleled inference speed of an optimized YOLOv5 model is non-negotiable for a high-volume consumer product line.

Understanding this trade-off between precision and throughput is key to architecting an effective solution. To better understand the landscape of defect analysis techniques, we can compare the performance and characteristics of several key architectures that have been rigorously tested:

| Architecture | Key Strength | Reported mAP (%) | Best For |

| Deformable Convolutional Network (DCN) | Adapts to geometric variations in defect shapes | ~77.3% | Detecting irregular and complex defects like ‘crazing’ or ‘rolled-in scale’. |

| Faster R-CNN (and derivatives) | High accuracy in localization (two-stage detector) | ~73-75% | Precise bounding box placement for well-defined defects. |

| YOLOv5 (and improved variants) | Extremely high inference speed (single-stage detector) | ~82.8% (Improved) | High-speed production lines requiring Real-time Defect Analysis. |

| RetinaNet | Balances speed and accuracy, handles class imbalance | ~74.6% | Environments with a high number of defect-free images. |

Navigating Intraclass and Interclass Complexity

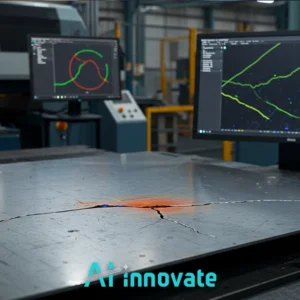

High-level accuracy metrics can sometimes mask the deeper challenges involved in industrial inspection. The true test of a robust Metal Defect Detection system lies in its ability to navigate two specific forms of complexity.

The first is intraclass complexity, which refers to the wide variations within a single defect category. For example, a “scratch” can be long, short, straight, or diagonal, and the model must correctly identify all variants as the same class.

This is more than a data challenge; it’s a physics problem. In industrial settings, greyscale datasets captured under variable lighting can wash out the subtle features that differentiate defect classes.

The issue is further compounded in “small target” detection, where defects comprise only a handful of pixels. In these cases, the model has severely limited information to analyze, making it incredibly difficult to extract meaningful features without advanced architectural components like attention mechanisms, which are specifically designed to amplify these weak signals.

The second, and often more difficult, challenge is interclass similarity. This occurs when different types of defects share visual characteristics. On the NEU steel dataset, defects like “rolled-in scale” and “pitted surfaces” can appear remarkably similar to an untrained eye—or an unsophisticated model.

The defect class “crazing,” a network of fine cracks, remains one of the most difficult to detect accurately across all benchmarked models, demonstrating the need for highly specialized architectures and training methodologies to overcome these nuanced visual challenges.

Streamlining the R&D Lifecycle

For ML engineers and R&D specialists, the process of developing and benchmarking these sophisticated models is fraught with challenges. It requires extensive data collection, significant investment in specialized industrial camera hardware, and long training cycles to test each new hypothesis or architecture.

This development bottleneck can delay innovation and increase project costs, creating a major barrier to implementing advanced AI for quality assurance.

The Virtual Prototyping Advantage

This is precisely the challenge AI-Innovate addresses with AI2Cam. As a sophisticated camera emulator, it decouples software development from hardware dependency, empowering technical teams to innovate faster and more efficiently. With AI2Cam, developers can:

- Accelerate Prototyping: Test new models and algorithms instantly without waiting for physical hardware setup.

- Reduce Costs: Eliminate the need to purchase and maintain a diverse array of expensive industrial cameras for development.

- Increase Flexibility: Simulate a wide range of camera settings, lighting conditions, and resolutions to build more robust models.

- Enable Remote Collaboration: Share virtual camera setups across distributed teams, fostering seamless collaboration.

By creating a high-fidelity virtual environment, AI2Cam transforms the R&D lifecycle from a slow, hardware-bound process into a rapid, software-driven one. Discover how AI2Cam can accelerate your machine vision development today.

Translating Accuracy into Operational ROI

For QA Managers and Operations Directors, technical metrics like mean Average Precision (mAP) are only meaningful when they translate into tangible business outcomes. The ultimate goal is not just to find defects, but to enhance profitability and operational excellence.

A highly accurate automated inspection system becomes a powerful financial lever for the entire manufacturing operation.

“High accuracy is not a feature; it’s a financial strategy.”

This is where the power of AI-Innovate’s AI2Eye system becomes evident. By delivering exceptional accuracy in real-time on the production line, AI2Eye moves beyond simple inspection to become a tool for machine learning for manufacturing process optimization. It enables a direct and measurable Return on Investment (ROI) by:

- Drastically reducing scrap material and product rework.

- Increasing throughput by enabling faster inspection than manual methods.

- Ensuring consistent, high-quality output that protects brand reputation.

AI2Eye doesn’t just find flaws; it strengthens your bottom line. To see how our AI-driven quality control system can be tailored to your specific needs, contact us to schedule a personalized demo.

Conclusion

The journey from manual inspection to intelligent, automated systems represents a paradigm shift in manufacturing. Achieving reliable Metal Defect Detection is a complex technical challenge that demands a deep understanding of model architectures, data complexities, and real-world operational needs. As we’ve seen, success requires both powerful development tools to innovate and robust, deployable systems to execute. AI-Innovate provides this comprehensive solution, empowering developers with AI2Cam and transforming factory floors with AI2Eye, ensuring quality from prototype to production.