This project combines computational materials science and Big Data analysis to generate a comprehensive digital twin of the aluminum strip casting process, aligned with the fourth wave of industry.

Current technologies in continuous aluminium sheet and plate production face two major challenges:

1) Any change in the alloy chemistry, strip thickness or casting speed requires tuning of process parameters. This adjustment is conventionally achieved by intelligent trial-and-error. The rate of success depends closely on the experience and knowledge of the production team.

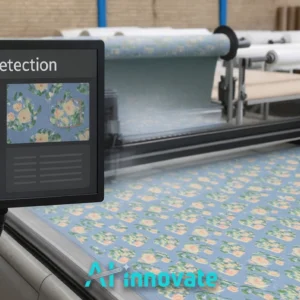

2) Meeting the important optical property requirements for sheets is a must. In next-generation strip casting facilities, the production speed can be as high as tens of meters per minute. Detecting the defects at such production speeds is almost impossible by conventional visual quality control.

At AI-innovate we have developed an aluminium strip casting assistive computational package that employs integrated computational materials engineering (ICME) and deep learning (DL) algorithms to integrate the simulation data and production line data to address these challenges.

The software package is capable of:

1) Modelling the progress of the process (this module addresses Challenge 1)

2) Automatically detecting/classifying defects in real-time (this module addresses Challenge 2)

3) Optimizing the process via feedback to the operational equipment (this module will empower the plant to run at optimum conditions and equip it with a predictive model to determine the likelihood of faulty production)

The essence of this project is aligned with the needs of Industry 4.0, providing a next level of efficiency and productivity in melt-to-coil aluminum strip production casting lines, beyond the technologies in conventional use today. The application of artificial intelligence and machine learning algorithms to optimize the casting process accurately and rapidly is informed by data generated from three independent sources: 1) telemetry data from embedded sensors, 2) optical and thermal images generated from the inspected surface, and, 3) a simulation module which models the casting process.

The proposed setup can be applied to any high-speed continuous production line including polymer sheets, fabric, coating, paint, and many others.

One Response

I would like to post an article http://fertus.shop/info/