The term “Smart Factory” is often lost in a cloud of marketing hype and abstract concepts, leaving technical leaders searching for a practical starting point. Behind the buzzwords, however, lies a tangible and powerful set of operational principles and technologies with profound real-world impact.

At AI-Innovate, our focus is on this practical application, engineering solutions that solve concrete problems. This article cuts through the noise. It serves as a technical blueprint, demystifying the smart factory by focusing on its functional components, its core data logic, and the measurable performance metrics that truly matter to your operation.

Turn Your Factory into a Smart One

Let AI inspect, analyze, and optimize – faster and smarter than ever.

The Cyber-Physical Production Core

At its heart, a smart factory operates on a cyber-physical production core. This concept transcends traditional automation by creating a deeply intertwined system where physical machinery and digital intelligence are no longer separate entities. Instead, they form a cohesive, self-regulating feedback loop.

Machinery on the factory floor is equipped with sensors that generate a constant stream of data, which is then analyzed by AI algorithms to optimize performance, predict failures, and adapt to new inputs in real time.

This dynamic integration results in a production environment that is not just automated, but truly autonomous and intelligent. The key characteristics of this core are what truly differentiate it from a standard automated setup. These attributes include:

- Real-Time Connectivity: A constant, bidirectional flow of information between machines, systems, and human operators, facilitated by the Industrial Internet of Things (IIoT).

- Decentralized Decision-Making: Individual components of the factory can make autonomous decisions to optimize their own operations, contributing to the overall efficiency of the system without constant central oversight.

- Self-Optimization: The system continuously learns from production data to refine processes, reduce waste, and improve output quality over time, embodying a state of perpetual improvement.

The Interconnected Technology Stack

A smart factory is not built on a single technology but on a sophisticated, interconnected technology stack where each layer builds upon the last to create a powerful whole. Understanding this stack is essential for grasping how data becomes insight and insight becomes action.

The foundational layers of this architecture work in concert, and I will now explore some of the most critical components of this stack:

Industrial IoT (IIoT)

This is the sensory nervous system of the factory. IIoT encompasses a vast network of sensors, actuators, and devices embedded within machinery and across the production line. These devices collect granular data on everything from temperature and vibration to material flow and energy consumption, providing the raw information that fuels the entire system.

AI-Driven Analytics

This is the brain of the operation. Artificial intelligence and machine learning algorithms process the massive datasets collected by the IIoT. They identify complex patterns, predict future outcomes (such as machine maintenance needs), and prescribe actions.

This is where raw data is transformed into strategic intelligence, making proactive and optimized production a reality. Practical Smart Factory Solutions are heavily reliant on the quality of these analytics.

Read Also: AI-Driven Quality Control – Transforming QC With AI

Digital Twins

Digital twins are virtual replicas of physical assets and processes. These simulations use real-time data from the factory floor to mirror the state of their physical counterparts. This allows operators and engineers to test new process configurations, simulate the impact of changes, and train operators in a risk-free virtual environment before implementing them in the real world.

The Industrial Data Intelligence Chain

Data is the lifeblood of a smart factory, but its true value is only unlocked when it moves through a structured “intelligence chain.” This process transforms raw, unstructured data points into actionable, strategic decisions that drive operational excellence.

This chain is not a simple linear path but a cyclical flow of information and action. You will find that the journey of data in a smart factory typically follows four distinct stages:

- Data Acquisition: This initial stage involves capturing vast amounts of data from every conceivable source on the factory floor, from IIoT sensors on machinery to enterprise resource planning (ERP) systems. The focus is on gathering a comprehensive and granular dataset.

- Data Aggregation: Raw data is often noisy and comes in various formats. In this stage, data is cleaned, contextualized, and aggregated in a centralized repository, often a cloud-based platform, making it accessible and ready for analysis.

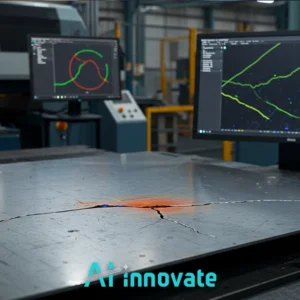

- Predictive Analysis: Here, AI and machine learning models are applied to the aggregated data to forecast future events. This can range from predicting when a specific component will fail to identifying subtle quality deviations in products before they become major defects.

- Automated Action: The final step closes the loop. Based on the insights generated from the analysis, the system triggers an automated response. This could be adjusting machine settings, alerting an operator to a potential issue, or even rerouting a production order.

Beyond Traditional Production Metrics

The implementation of smart factory principles allows organizations to move beyond traditional, reactive metrics and embrace a new set of benchmarks that reflect a more proactive and intelligent operational model.

While metrics like overall equipment effectiveness (OEE) remain important, they are now supplemented by more forward-looking indicators. This evolution in measurement is a core benefit of adopting advanced Smart Factory Solutions. To better illustrate this shift, let’s compare the old with the new in the following table:

| Traditional Metric (Reactive) | Smart Metric (Proactive) |

| Historical Downtime Analysis | Predictive Maintenance Alerts |

| Post-Production Quality Checks | Real-Time Anomaly Detection |

| Standard Energy Consumption | Demand-Based Energy Optimization |

| Fixed Production Schedules | Dynamic Resource Allocation |

This shift allows QA Managers and Operations Directors to transition from a mindset of “analyze and repair” to one of “predict and prevent.” Instead of identifying defects after the fact, systems can now flag potential quality issues in real time as products move down the line, drastically reducing waste and scrap.

Similarly, predictive maintenance alerts based on a machine’s actual condition, rather than a fixed schedule, all but eliminate unplanned downtime, directly boosting efficiency and throughput.

Redefining the Operator’s Role

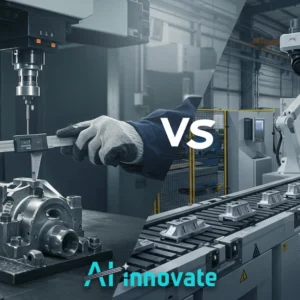

The rise of the smart factory does not signal the end of the human workforce; rather, it elevates it. The role of the factory floor operator is undergoing a significant transformation, evolving from manual labor to data-driven supervision.

As repetitive, physically demanding, and error-prone tasks are automated, human workers are freed to focus on higher-value activities that require critical thinking, complex problem-solving, and creativity—skills that even the most advanced AI cannot replicate.

In this new paradigm, the operator becomes a “process overseer” or a “system analyst.” Armed with intuitive dashboards and real-time data visualizations, they monitor the health of the automated systems, interpret the insights generated by AI, and make strategic interventions when necessary.

Their work becomes less about physically running the machines and more about ensuring the entire intelligent system runs smoothly and efficiently. This creates a more engaging and technically skilled workforce, fostering a culture of continuous improvement and innovation from the ground up.

Applied AI on the Factory Floor

Translating the concepts of a smart factory into tangible results requires specialized, purpose-built tools that bridge the gap between data and action. Effective Smart Factory Solutions are not one-size-fits-all;

they are targeted technologies designed to solve specific, high-stakes industrial challenges. At AI-Innovate, we develop such practical tools for both industrial leaders and technical developers. To provide a clearer picture of how this is achieved, let’s explore our core product offerings:

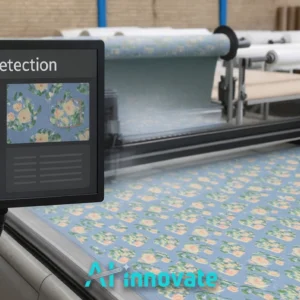

AI2Eye: Intelligent Vision in Action

For QA Managers struggling with the high cost and inconsistency of manual inspection, AI2Eye offers a direct solution. It is an advanced AI-powered machine vision system that automates real-time quality control directly on the production line.

By identifying subtle surface defects and process inefficiencies that the human eye can miss, AI2Eye provides an immediate and clear ROI. Its core benefits include:

- Drastic Waste Reduction: Catches defects early to minimize scrap.

- Enhanced Process Efficiency: Analyzes production data to identify and remove bottlenecks.

- Guaranteed Quality Standards: Ensures every product meets the highest quality specifications.

AI2Cam: Accelerating Vision Development

For ML Engineers and R&D Specialists, the reliance on physical hardware can create significant project delays. AI2Cam is a powerful camera emulator that decouples software development from hardware dependency.

It allows developers to simulate a wide range of industrial cameras and imaging conditions directly from their computers, empowering them to build, test, and prototype machine vision applications faster and more cost-effectively than ever before. This is the kind of practical tool that is vital to the ecosystem of Smart Factory Solutions.

For teams looking to implement or accelerate their machine vision projects, exploring these tools can provide a significant competitive advantage. We encourage you to review their technical specifications to see how they can directly address your operational and development challenges.

The Autonomous Production Horizon

Looking forward, the trajectory of smart factory development points toward a horizon of near-total autonomy. The ultimate vision is the “lights-out” factory—a facility that can run independently, 24/7, with minimal human intervention.

While we are not there yet, the building blocks are already in place. The next evolution will see the integration of entire supply chains, with factories that can automatically adjust production based on incoming orders, material availability, and even real-time market demand.

We can expect to see self-optimizing networks where smart factories communicate with each other and with suppliers and logistics partners to create a seamless, hyper-efficient production ecosystem.

This will enable mass personalization at scale, where products are manufactured to individual customer specifications with the efficiency of mass production. This future is not a distant dream; it is the logical next step in the journey of industrial digitalization, and the Smart Factory Solutions of today are paving the way for the autonomous operations of tomorrow.

Cybersecurity and Data Privacy: Protecting the Heart of Smart Factory Solutions

In today’s connected world, the same technology that makes smart factory solutions powerful also brings new risks. A modern smart factory connects machines, sensors, cloud systems, and AI tools, all sharing important data in real time. This constant flow of information helps the factory work faster and smarter, but it also creates more chances for cyberattacks.

Keeping a smart factory safe means building strong protection at every level. On the factory floor, dividing networks into separate zones and using “zero-trust” security can stop attackers from moving freely if they get in. For the data itself, using encryption, secure logins, and constant monitoring helps make sure the information stays accurate and private. It’s also important to follow privacy laws, like GDPR or CCPA, from the start, not as an afterthought.

One weak sensor, an outdated security patch, or a wrongly set firewall could shut down production, break important systems, or damage the company’s reputation.

That’s why modern smart factory solutions are making cybersecurity part of their design from day one. Tools like AI-based threat detection, automated responses to attacks, and real-time monitoring are now just as important as predictive maintenance or quality checks. By taking security seriously, companies can enjoy all the benefits of smart factory solutions, while protecting their data, keeping production running, and maintaining customer trust.

Conclusion

The smart factory represents a paradigm shift in manufacturing, moving from siloed automation to a deeply integrated, data-driven, and intelligent ecosystem. It is not just about technology; it is about fundamentally changing the way production is managed, measured, and optimized. Adopting these principles is no longer a choice but a competitive necessity in the global marketplace. As a strategic partner in this transformation, AI-Innovate provides the practical, powerful AI tools needed to turn this industrial vision into a reality, ensuring your operations are not just smarter, but also more efficient and resilient.