In modern manufacturing, the demand for flawless materials is absolute, as even microscopic deviations can compromise structural integrity. Human-led quality control, while foundational, is inherently limited by fatigue and perceptual variability. AI-Innovate is at the forefront of this industrial evolution, delivering intelligent systems that redefine precision.

This article moves beyond theory to provide a deep, technical dive into the architecture, challenges, and strategic implementation of AI for Material Defect Identification, offering a clear roadmap for achieving unparalleled quality and operational efficiency in your processes.

The Imperative of Micro-Level Integrity

The structural and functional promise of any product is predicated on the microscopic integrity of its base materials. A subtle scratch in a metal sheet, a minuscule porosity in a polymer, or an inconsistent fiber in a textile composite is not merely a cosmetic issue; it is a potential point of failure.

These imperfections can initiate stress fractures, reduce material lifespan, and ultimately lead to catastrophic breakdowns. For industrial leaders, the consequences extend far beyond the factory floor, manifesting in significant financial and reputational damage.

The proactive detection of these micro-flaws is thus not a luxury but a fundamental necessity for sustainable, high-quality production. Understanding these cascading consequences, as outlined below, highlights the limitations of traditional inspection and the critical need for a technological shift.

- Increased Operational Costs: Arising from material waste, product recalls, and warranty claims.

- Reputational Damage: Stemming from product failures that erode customer trust and brand loyalty.

- Safety Liabilities: The critical risk of harm caused by faulty components in sectors like automotive or construction.

Cognitive Vision for Industrial Scrutiny

Transcending conventional machine vision for defect detection, modern AI employs a more sophisticated paradigm: cognitive vision. This approach doesn’t just “see” an image; it interprets and contextualizes visual data with near-human-like perception.

At its core, this technology leverages advanced algorithms to analyze materials at a granular level, creating a robust framework for AI for Material Defect Identification. To appreciate its power, it’s essential to understand its foundational pillars, which are detailed further below.

Core Algorithmic Functions

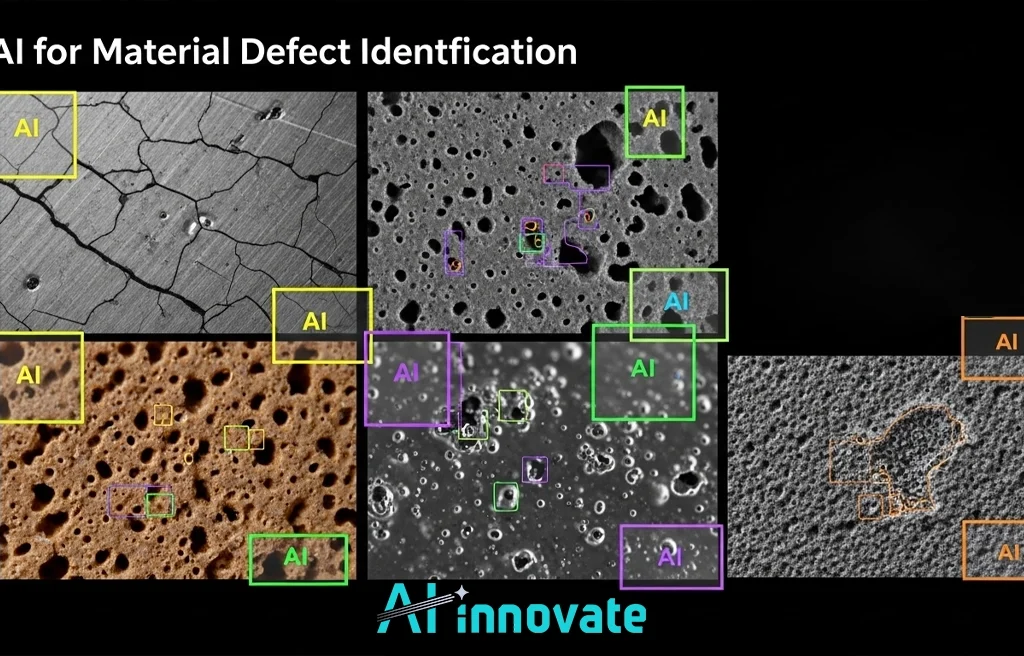

Cognitive vision systems are predominantly powered by Convolutional Neural Networks (CNNs). These complex deep-learning models are trained on vast datasets of images to recognize patterns.

They scan materials pixel by pixel, identifying anomalies that deviate from the established “perfect” baseline. Unlike simple template matching, CNNs can detect and classify a wide spectrum of unpredictable defects—such as varied metal defect detection or subtle discolorations—even under fluctuating lighting conditions.

Essential Hardware Components

The effectiveness of these algorithms relies on a synergistic hardware setup. This includes high-resolution industrial cameras, specialized lighting to eliminate shadows and glare, and powerful processing units (typically GPUs) capable of executing complex computations in real-time.

The precise calibration and integration of this hardware are critical for capturing the high-fidelity data needed for accurate analysis.

A critical aspect of deploying these systems efficiently is the use of transfer learning. Instead of training a neural network from scratch, which demands enormous datasets and computational power, developers often start with a pre-trained model—one that has already learned to recognize general features from millions of images.

This foundational model is then fine-tuned on a smaller, specific dataset of the target material, such as metal surfaces or woven textiles. This technique dramatically reduces development time and data requirements, making advanced AI more accessible for specialized industrial applications.

Bridging the Data-Reality Gap

One of the most significant technical hurdles in implementing AI for quality assurance is bridging the gap between curated training datasets and the chaotic reality of a live production environment.

An AI model is only as intelligent as the data it learns from. In industrial settings, acquiring a sufficiently large and diverse dataset of “defective” examples can be impractical, as well-managed processes produce few flaws. This “data scarcity” problem poses a major challenge. The table below illustrates how developers are overcoming this by complementing real-world data with synthetically generated assets.

| Feature | Real Data | Synthetic Data |

| Source | Physical products from the production line | Computer-generated or simulated images |

| Cost & Time | High; requires manual collection & labeling | Low; can be generated programmatically |

| Diversity & Volume | Limited to observed defects | Virtually infinite; can create rare defects |

| Annotation Quality | Can be inconsistent | Pixel-perfect and automatically annotated |

This hybrid approach allows for the development of highly robust and accurate models, even when real-world defect data is scarce.

Optimizing Production with Intelligent Oversight

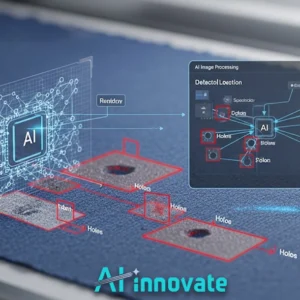

True AI for Material Defect Identification moves beyond the passive role of inspection and into the active realm of process optimization. An intelligent system does not merely flag a defect; it provides a stream of data that offers deep insights into the manufacturing process itself.

By analyzing the frequency, type, and location of recurring flaws, these systems help QA managers and operations directors pinpoint systemic issues within the production line. Is a specific machine malfunctioning? Is a raw material batch subpar? Intelligent oversight answers these questions with empirical data, enabling machine learning for manufacturing process optimization.

This is precisely where AI-Innovate’s flagship system, ai2eye, transforms operations. It functions as an integrated layer of intelligence on the factory floor, delivering not just detection but actionable insights. It empowers manufacturers to make data-driven decisions that enhance efficiency and quality simultaneously. Key benefits include:

- Drastic Waste Reduction: Early detection prevents defective materials from moving down the line.

- Boosted Throughput: Real-time analysis identifies and helps resolve bottlenecks faster.

- Guaranteed Quality: Ensures every product meets the highest standards, fortifying brand reputation.

Emulating Reality to Accelerate Innovation

For the ML engineers and R&D specialists tasked with building the next generation of industrial AI, the development cycle can be a frustrating bottleneck. Progress is often shackled to the availability of physical hardware, leading to project delays and inflated costs. Prototyping and testing new models requires specific cameras and setups that may not be readily accessible, stifling experimentation and remote collaboration.

AI-Innovate addresses this critical challenge with ai2cam, a powerful camera emulator that decouples software development from hardware dependency. This virtual camera tool allows developers to simulate a wide array of industrial cameras and imaging conditions directly from their computers.

By emulating reality, ai2cam empowers developers to build, test, and refine their applications in a flexible and cost-effective virtual environment. It provides the agility needed to innovate without constraints, accelerating the entire development lifecycle. The advantages are immediate and impactful:

- Faster Prototyping: Rapidly test ideas without waiting for hardware.

- Significant Cost Reduction: Eliminates the need for expensive cameras for R&D.

- Unmatched Flexibility: Simulate diverse testing scenarios on-demand.

- Seamless Remote Collaboration: Enables teams to work in unison from anywhere.

Quantifying Quality Beyond Binary Judgments

The evolution of automated inspection has moved beyond simple “pass/fail” decisions. A mature AI for Material Defect Identification system offers the ability to quantify quality with remarkable precision.

Instead of a binary judgment, these systems can classify defects by type, measure their severity on a continuous scale, and log their exact coordinates on a material’s surface. This granular data allows for a far more nuanced understanding of quality control. For instance, a system can distinguish between a minor, acceptable surface scuff and a critical micro-fracture, applying different business rules accordingly.

This capability transforms quality data from a simple alert mechanism into a rich analytical resource for continuous improvement.

Furthermore, this quantification serves as the foundation for predictive quality analytics. By analyzing historical defect data in correlation with process parameters (e.g., machine temperature, material tension), AI models can identify subtle precursor patterns that signal impending quality degradation.

This allows industrial leaders to shift from a reactive to a proactive stance—intervening to adjust a process before it starts producing out-of-spec products. It’s a powerful step towards achieving zero-defect manufacturing by forecasting and mitigating issues before they materialize on the production line.

Architecting a Resilient Quality Infrastructure

Ultimately, the goal is not just to implement a standalone inspection tool but to architect a resilient and interconnected quality infrastructure. This involves integrating the insights from your AI-driven quality control system with higher-level manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

When defect data flows seamlessly across the organization, it becomes a strategic asset. This integration creates a closed-loop system where production parameters can be automatically adjusted in response to quality trends, building an operation that is not only efficient but also adaptive and self-optimizing. Such an infrastructure makes quality an inherent attribute of the entire production process, not just a final checkpoint.

Building this resilient infrastructure also involves considering the human and security elements. A successful integration empowers the human workforce, transforming operators from manual inspectors into system supervisors who interpret AI-driven insights to make strategic decisions.

Simultaneously, as these systems become more connected, robust cybersecurity protocols are essential. Protecting the quality control data and the integrity of the AI models from external threats is paramount to maintaining the trustworthiness and reliability of the entire manufacturing operation, ensuring the infrastructure is not just intelligent but also secure.

Conclusion

The journey from manual inspection to intelligent quality assurance is a transformative one. It begins with acknowledging the imperative of micro-level integrity and leveraging the power of cognitive vision to achieve it. By bridging the data gap and using intelligent systems like ai2eye and ai2cam, companies can move beyond mere defect detection to true process optimization. Architecting this technology into a resilient infrastructure solidifies a new standard of operational excellence. AI-Innovate is committed to delivering these practical, powerful solutions.