The structural integrity of industrial components and civil infrastructure is paramount to operational safety and economic stability. While traditional inspection methods have served us for decades, they are increasingly unable to meet the demands for speed, accuracy, and scalability required in modern industry.

At AI-Innovate, we bridge this gap by engineering practical AI solutions that address these critical challenges. This article provides a comprehensive technical analysis of Surface Crack Detection Using Deep Learning, exploring the core technologies, model performance metrics, and real-world industrial applications that are defining the future of automated quality assessment.

Next-Level Surface Crack Detection Starts Here

Let AI detect, analyze, and classify surface cracks using Deep Learning — smarter, faster, and more accurately than ever.

The Imperative for Automated Structural Assessment

The reliance on manual inspection for surface defect detection is fraught with inherent limitations that directly impact a company’s bottom line and safety record. Human inspectors, no matter how skilled, are susceptible to fatigue, subjective judgment, and physical limitations, leading to inconsistent and often slow assessments.

This manual process is not only labor-intensive and expensive but also poses significant risks in hazardous environments like pipelines or large-scale constructions. The transition to automated systems is no longer a luxury but a strategic necessity.

By automating inspections, industries can implement continuous, objective monitoring that drastically reduces error rates, minimizes production downtime, and creates a safer working environment for personnel.

Convolutional Neural Networks as Digital Inspectors

At the heart of modern automated inspection are Convolutional Neural Networks (CNNs), a class of deep learning models designed to process and analyze visual data with remarkable proficiency.

Inspired by the human visual cortex, CNNs automatically learn to identify intricate patterns and features directly from images. Instead of being explicitly programmed to find specific types of cracks, a CNN learns the defining characteristics of a defect—its texture, shape, and orientation—by analyzing thousands of example images.

This process enables the model to identify flaws with a high degree of accuracy, even when faced with variations in lighting, surface material, or camera angle. To better understand their function, the operational flow of a CNN can be broken down into these core stages:

- Image Ingestion: The network receives a raw pixel image as its primary input.

- Hierarchical Feature Extraction: Through a series of convolutional and pooling layers, the network progressively extracts features, starting from simple edges and textures and building up to complex patterns that signify a crack.

- Classification or Localization: A final set of layers processes these features to either classify the entire image as “cracked” or “uncracked,” or to precisely locate the crack within the image.

Read Also: Surface Defect Detection Deep Learning – End Human Error

Comparative Model Performance and Precision

The effectiveness of any deep learning system is measured by its performance. Different models and techniques yield varying levels of precision, and selecting the right architecture is critical for success.

Research demonstrates that while a standard CNN can achieve a respectable accuracy of 89%, the application of transfer learning—using a pre-trained model like ResNet50 as a starting point—can elevate this performance to 94%, even with limited datasets.

This highlights the power of leveraging existing knowledge to accelerate development. The choice of model architecture has a profound impact on outcomes, making Surface Crack Detection Using Deep Learning a field where technical specificity matters immensely.

For a clearer perspective, the following table compares prominent models based on findings from technical studies:

| Model | Common Dataset | Reported Accuracy / Score | Source (Conceptual) |

| Baseline CNN | Public Concrete Datasets | 89% | Academic Studies |

| ResNet50 (Transfer Learning) | Public Concrete Datasets | 94% | Academic Studies |

| Various CNNs | 40,000 Image Dataset | 88.21% – 98.60% | MDPI, arXiv |

| YOLOv8 | Pavement/Infrastructure | 0.939 (mAP50-95) | Ultralytics |

Instance Segmentation with YOLOv8

Modern approaches go beyond simple classification. Models like YOLOv8 perform instance segmentation, a sophisticated technique that not only detects a crack but also outlines its exact shape pixel by pixel.

A system built on YOLOv8 has been shown to achieve a mean Average Precision (mAP) score of 0.939, a testament to its high accuracy in real-world scenarios. This capability is invaluable for quantitative analysis, allowing engineers to calculate the precise area and length of a defect to assess its severity and prioritize repairs.

Dataset Integrity and Preprocessing Efficacy

The adage “garbage in, garbage out” is especially true for deep learning systems. The performance of any model is fundamentally tied to the quality and structure of the data it is trained on.

A widely-used public dataset for this task consists of 40,000 images, each 227×227 pixels, created from 458 high-resolution photographs of concrete surfaces. These datasets must be carefully curated and preprocessed to ensure the model learns relevant features rather than noise.

The preprocessing pipeline involves several key steps that can influence model outcomes, as we outline below:

- Image Splitting: Datasets are typically divided into training and testing sets, often with an 80/20 or 85/15 split to ensure unbiased evaluation.

- Grayscale Conversion: Research indicates that converting images to grayscale does not harm performance. Models trained on grayscale images achieved an F1-score of 99.549%, virtually identical to the 99.533% from models trained on full-color RGB images, suggesting color data is not essential for this task.

- Data Augmentation: Techniques like random rotations, flips, and brightness adjustments are often applied to artificially expand the dataset, making the final model more robust and adaptable to varied real-world conditions.

Industrial Adoption in Automotive and Infrastructure

The theoretical power of Surface Crack Detection Using Deep Learning translates directly into tangible value across multiple industries. Leading manufacturers and infrastructure managers are actively deploying these technologies to move beyond the limitations of legacy systems and unlock new levels of efficiency and safety. The practical successes in these fields serve as a clear blueprint for others considering adoption.

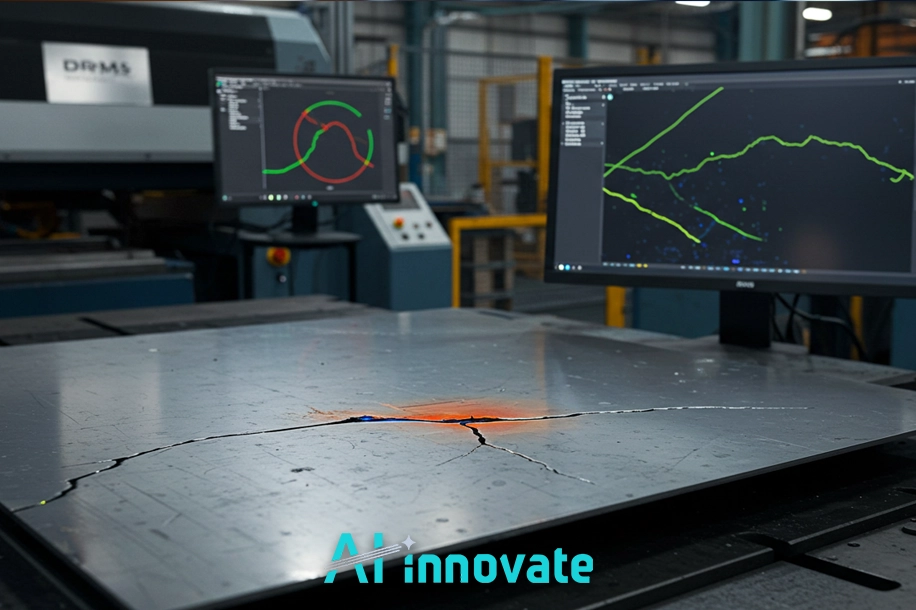

Case Study: Automotive Press Shop Inspection

In the highly competitive automotive sector, quality is non-negotiable. Carmaker Audi has implemented a deep learning system in its press shops to inspect sheet metal parts for microscopic cracks.

This AI-powered solution has successfully replaced traditional machine vision software that was often unreliable and sensitive to lighting changes. The new system identifies defects with near-pixel perfection, ensuring that only flawless components proceed to the assembly line, thereby reducing waste and upholding the highest quality standards.

Applications in Civil Infrastructure

The principles of Surface Crack Detection Using Deep Learning are equally transformative for civil infrastructure management. This technology is being used to automate the inspection of bridges, roads, and tunnels, where early and accurate defect detection is critical for public safety.

Furthermore, in the oil and gas sector, automated systems monitor pipelines and storage tanks, identifying potential points of failure before they can escalate into catastrophic incidents, thus optimizing maintenance schedules and preventing costly operational disruptions.

From Model to Manufacturing Line

Translating a successful model from a development environment to a robust industrial application presents its own set of challenges. At AI-Innovate, we provide the tools to bridge this gap:

AI2Eye: Intelligent Quality Control on the Factory Floor

Our AI2Eye system is a complete, real-time quality control solution that brings the power of AI directly to your manufacturing line:

- Reduces material scrap and product defects.

- Boosts production throughput and efficiency.

- Guarantees superior product quality and brand reputation.

AI2Cam: Accelerating Vision Development

For R&D teams, our AI2Cam virtual camera emulator streamlines the entire development lifecycle:

- Enables rapid prototyping without physical hardware.

- Reduces costs associated with purchasing and maintaining cameras.

- Provides the flexibility to simulate countless testing scenarios.

Conclusion

Investing in automated inspection is a strategic imperative for any organization committed to quality, safety, and operational excellence. The continued advancement in Surface Crack Detection Using Deep learning, especially with emerging concepts like Physics-Informed Neural Networks, promises even more intelligent and reliable systems. Our mission at AI-Innovate is to deliver these powerful, practical AI solutions today.