Industrial leaders rightly demand clear, quantifiable ROI, while their R&D engineers grapple with the technical hurdles of hardware-dependent development cycles. Our work at AI-Innovate thrives at the intersection of these two worlds. We create robust solutions that deliver proven financial value while simultaneously empowering technical teams with agile, powerful development tools.

This article serves as a shared language, breaking down AI Automation in Manufacturing into its essential components—from strategic financial impact to tactical development accelerators—to align high-level business objectives with flawless technical execution on the ground.

Automated , Accurate , Always-On

Replace human fatigue with 24/7 AI inspection.

Recalibrating Production Fundamentals

The integration of artificial intelligence into manufacturing is not an exploratory trend; it is a core economic driver with measurable momentum. This foundational shift, central to the Industrie 4.0 vision, is creating a new competitive baseline where factories operate as interconnected, intelligent ecosystems. To grasp the scale of this global transformation, consider these key economic and market indicators:

- The global AI in manufacturing market is projected to expand at a compound annual growth rate (CAGR) of an astounding 44.5% in the coming years.

- In China, a manufacturing powerhouse, the market size for “AI + Manufacturing” reached 5.6 billion yuan in 2023 and is on track to hit 14.1 billion yuan by 2025.

- Across the board, 64% of manufacturers deploying AI have already experienced a positive return on investment, with nearly a third realizing returns of $2 to $5 for every $1 invested.

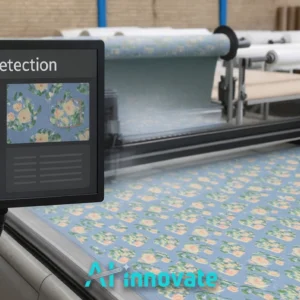

From Human Eye to Algorithmic Precision

For Quality Assurance managers, the pursuit of perfection is a constant battle against human limitation. Traditional manual inspection, while valuable, has a performance ceiling, with human inspectors typically achieving 80% to 90% accuracy under optimal conditions.

This creates a persistent risk of defects reaching the customer, impacting brand reputation and incurring costs. The transition from human subjectivity to algorithmic certainty marks a paradigm shift in quality control.

The impact of AI Automation in Manufacturing is most evident when comparing these two approaches directly, as the following points illustrate. The contrast in performance is stark:

- Human Inspection: Prone to fatigue, inconsistency, and subjective judgment. Accuracy rates fluctuate, and it is ill-suited for high-speed, high-volume production lines.

- AI-Powered Vision Inspection: Delivers objective, consistent, and tireless analysis. These systems can achieve accuracy rates of up to 99.9%, identifying micro-defects invisible to the human eye in real-time. For instance, BMW successfully reduced its defect rate by 30% in one year by implementing such a system.

Read Also: Defect Detection in Manufacturing – AI-Powered Quality

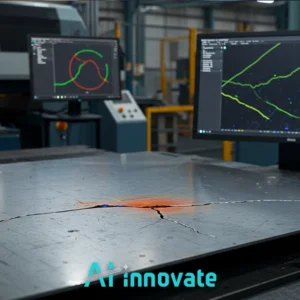

Operational Foresight Through Data

Beyond quality control, the greatest value unlocked by AI often comes from its ability to provide operational foresight. For Operations Directors, unplanned downtime is a primary driver of inefficiency and lost revenue.

Predictive maintenance flips this script, transforming equipment management from a reactive exercise into a proactive strategy. By analyzing continuous streams of sensor data, algorithms can identify subtle anomalies and predict equipment failures before they occur.

This application of AI Automation in Manufacturing is not theoretical; its return on investment is proven and significant. According to extensive industry data, manufacturers implementing predictive maintenance have reported a reduction in equipment breakdowns by as much as 70% and a corresponding decrease in maintenance costs by 25%.

This foresight allows for scheduled, efficient repairs, minimizing disruption and maximizing the operational lifespan of critical machinery. It is about anticipating failure, not just reacting to it.

Read Also: Anomaly Detection in Manufacturing – Process Insights

Prototyping Beyond Physical Constraints

For the technical developers and Machine Learning engineers tasked with creating these intelligent systems, a different kind of bottleneck exists: physical camera dependency. The traditional process of developing machine vision algorithms requires access to specific, often expensive, industrial cameras and hardware.

This creates a linear, slow, and inflexible workflow where software development is tethered to hardware availability. Project timelines are extended, and experimentation is stifled by the logistical challenges of setting up complex physical testbeds.

This is where the concept of virtual camera emulation becomes a strategic enabler. By simulating a wide range of industrial cameras and imaging conditions in a purely software environment, developers can decouple their work from hardware constraints.

This allows for rapid prototyping, parallel development, and the ability to test algorithms against thousands of scenarios without a single piece of physical equipment, dramatically accelerating the innovation lifecycle.

Engineer Your Competitive Edge

Translating these advanced concepts into deployable, real-world tools is central to our mission. We build the solutions that bridge the gap between industrial challenges and algorithmic power.

AI2Eye: Real-Time Industrial Inspection

Our AI2Eye system directly addresses the need for superior quality control, delivering the algorithmic precision required to reduce waste and ensure product integrity on the factory floor.

AI2Cam: Accelerated Vision Prototyping

Our AI2Cam virtual camera emulator empowers your development teams to innovate faster, breaking the reliance on physical hardware and reducing R&D costs.

Connect with our specialists to explore how these solutions can be integrated into your workflow.

The Pragmatic Path to Integration

A successful implementation requires a clear-eyed view of the potential hurdles. To build a robust and scalable system, industrial leaders must address several well-documented challenges. Based on industry-wide experiences, here are the most critical factors to consider on the path to integration:

- Legacy Systems Integration: Many manufacturing facilities operate on a combination of modern and legacy equipment. Integrating new AI platforms with older, non-digital systems can be complex and requires careful planning and specialized expertise.

- Data Quality and Governance: AI algorithms are only as effective as the data they are trained on. Establishing processes for collecting, cleaning, and labeling high-quality data is arguably the most critical and resource-intensive aspect of any AI Automation in Manufacturing project.

- Specialized Skill Sets: The demand for data scientists, ML engineers, and AI specialists far outstrips the current supply. Companies must invest in upskilling their existing workforce or partner with external experts to fill this critical talent gap.

- Workforce Adoption: The introduction of automation can create anxiety among employees. Research indicates that workers concerned about their jobs being replaced are 27% less likely to remain with their employer, making transparent communication and change management essential.

Conclusion

The adoption of artificial intelligence in manufacturing is not merely an upgrade; it is a redefinition of what is possible in terms of quality, efficiency, and innovation. The evidence shows that AI Automation in Manufacturing delivers a decisive competitive advantage. By partnering with experts and leveraging practical tools, you can successfully navigate the path from concept to full-scale, intelligent production.