In markets defined by razor-thin profit margins, product defects are not mere flaws—they are direct threats to financial viability. The escalating costs of manual inspection, rework, and waste represent a critical operational liability that traditional methods cannot solve.

AI-Innovate confronts this economic challenge directly, engineering solutions to fortify your bottom line. This article provides a definitive guide to implementing AI for Quality Assurance, moving beyond theory to present practical frameworks that transform quality control from a reactive expense into a strategic, profit-generating asset for your enterprise.

Smarter Control , Higher Output

Let AI run the rules so you can run the results.

Transcending Manual Inspection Limits

For decades, manual inspection has been the cornerstone of quality assurance. However, its inherent subjectivity and operational friction create significant hidden costs and production vulnerabilities.

Relying on human perception is not scalable and introduces variables that are difficult to control, particularly in high-volume manufacturing where fatigue and cognitive bias can lead to inconsistent defect detection.

The financial impact of catching a defect late in the cycle is exponentially higher than preventing it at the source. This reactive model is ill-suited for the demands of modern industry. A deeper look reveals several fundamental constraints.

Scalability Issues

Manual inspection cannot scale proportionally with increased production speed or complexity without a linear, and often unsustainable, increase in labor costs.

Human Error

Even the most skilled inspectors are susceptible to fatigue and perception errors, leading to missed defects or false positives that disrupt workflow.

Inconsistency

Different inspectors may interpret quality standards differently, resulting in a lack of standardized, repeatable outcomes across shifts or facilities.

High Latency

The delay between inspection, data logging, and analysis means that by the time a recurring issue is identified, a significant volume of faulty product may have already been produced.

Algorithmic Certainty in Process Control

The transition away from manual inspection is enabled by a fundamental shift in philosophy: replacing subjective human judgment with algorithmic certainty. This is the core principle of effective AI for Quality Assurance.

By leveraging machine learning models, systems can analyze vast datasets from production lines to identify subtle patterns and correlations that are invisible to the human eye. This is not about merely automating an existing process, but about re-imagining it entirely.

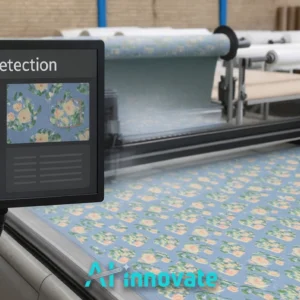

Quality control evolves from a reactive, after-the-fact activity into a predictive, in-process function. The technology of machine vision for defect detection, for example, does more than just replicate human sight; it provides a level of precision and endurance that is superhuman.

It operates continuously, applying the exact same criteria to every single product, 24/7. This consistency eliminates the variables of human error and provides a stream of reliable, structured data that can be used not just for defect identification but for true process optimization.

The system learns what constitutes an acceptable deviation and what signals a systemic flaw, allowing for interventions before significant waste is generated.

Architecting an Intelligent Assurance Framework

Successfully deploying AI for Quality Assurance requires more than just acquiring technology; it demands a structured, systematic implementation. An effective framework ensures that AI models are not only accurate but also robust, scalable, and aligned with specific operational goals.

This process transforms raw data into actionable intelligence. The architecture of such a system can be understood through three core, iterative phases that form a cycle of continuous improvement.

Data Acquisition and Labeling

This foundational stage involves collecting high-quality visual or sensor data from the production line. The data—images of products, sensor readings, etc.—must be comprehensive and representative of all possible scenarios, including normal variations and a wide array of defects.

This dataset is then meticulously labeled by domain experts to “teach” the AI what to look for. The quality of this initial dataset directly determines the performance and accuracy of the final system.

Model Training and Validation

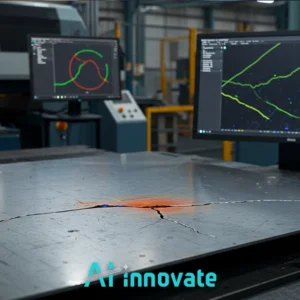

Using the labeled data, Machine Learning in Quality Control are trained to differentiate between acceptable products and various types of defects. The system learns the intricate visual signatures of flaws like cracks, discolorations, or misalignments.

This phase involves rigorous testing and validation using separate datasets to ensure the model can generalize its knowledge to new, unseen examples and avoid “overfitting” to the training data.

Deployment and Monitoring

Once validated, the model is deployed into the live production environment. This is not a final step but the beginning of an ongoing process. The system’s performance is continuously monitored, and its decisions are periodically reviewed.

This feedback loop allows the model to be retrained and refined over time, adapting to changes in product specifications, materials, or environmental conditions, thus ensuring its long-term accuracy and relevance.

Real-Time Quality Intelligence on the Line

The true power of modern AI for Quality Assurance is realized when these intelligent frameworks are applied directly on the production line, providing immediate feedback. This concept of real-time defect analysis shifts the paradigm from post-production sampling to 100% in-line inspection.

Every item is scrutinized as it is made, creating an unprecedented level of process visibility. This capability allows manufacturers to identify and correct issues instantly, drastically reducing scrap rates and optimizing material usage.

Solutions like AI-Innovate’s ai2eye are engineered specifically to deliver this on-the-line intelligence, transforming factories into smarter, more efficient operations. The tangible impact of this approach is best understood by connecting specific features to their direct financial outcomes.

| Feature |

Impact on ROI |

| Instant Defect Detection | Minimizes material waste and rework costs. |

| Process Drift Analysis | Prevents large-scale quality failures by flagging minor deviations. |

| Root Cause Data-Logging | Reduces troubleshooting time for engineering teams. |

| Automated Reporting | Frees up QA personnel for higher-value strategic tasks. |

Accelerating Innovation with Camera Emulation

For the technical developers and R&D specialists building these next-generation systems, the primary bottleneck is often not the algorithm but the hardware. The reliance on physical industrial cameras for developing and testing machine vision applications creates significant delays and costs.

A strategic approach to bypass this hurdle is the use of camera emulators. These software tools create a virtual development environment, decoupling software innovation from hardware availability. This approach unlocks several key advantages that directly address development bottlenecks:

- Faster Prototyping: Developers can test algorithms against thousands of simulated camera models and imaging conditions without waiting for physical hardware to be procured and configured.

- Significant Cost Reduction: Eliminates the substantial capital expenditure and maintenance costs associated with owning a diverse inventory of industrial cameras for testing.

- Enhanced Flexibility: Allows for the simulation of challenging or rare scenarios (e.g., poor lighting, high-speed motion) that are difficult and time-consuming to replicate physically.

- Seamless Remote Collaboration: Engineering teams can work and iterate on the same project from anywhere in the world, sharing a virtual environment instead of physical equipment. Tools like AI-Innovate’s ai2cam are designed to provide this exact flexibility, empowering developers to innovate faster and more affordably.

Evolving Professional Roles in the AI Era

The integration of AI for Quality Assurance does not render the human expert obsolete; rather, it elevates their role. As autonomous systems take over repetitive and tedious inspection tasks, QA professionals are freed to focus on more strategic, high-impact activities.

Their function evolves from a manual executor to a system strategist and data analyst. This transition empowers teams to add more value than ever before. The modern quality expert is no longer defined by their ability to spot a flaw, but by their ability to manage and interpret the systems that do.

Their expertise is redirected toward algorithm oversight, process improvement initiatives based on AI-driven insights, and managing the edge cases that still require human cognition. This shift transforms the QA team into a hub of innovation for industrial process control, driving continuous improvement initiatives that have a measurable impact on the entire operation. It is a fundamental enhancement of human capability, not a replacement.

Measuring the Return on Quality Investment

For industrial leaders, the decision to invest in any new technology hinges on a clear and quantifiable return on investment (ROI). Fortunately, the impact of implementing an intelligent quality framework is highly measurable.

Unlike abstract enterprise software, the benefits manifest directly on the factory floor in the form of concrete operational and financial improvements. To build a compelling business case, leaders can focus on tracking a few key performance indicators. A simple approach involves these steps:

- Benchmark Current Performance: Establish a baseline by measuring key metrics before implementation, such as scrap rate, units produced per hour (throughput), and man-hours spent on manual inspection.

- Track Post-Implementation Changes: After deployment, continuously monitor the same metrics. Quantify the reduction in waste, the increase in production efficiency, and the reallocation of human resources.

- Calculate Financial Impact: Translate these operational improvements into financial terms. For example, calculate the dollar value of saved material from a reduced scrap rate or the increased revenue potential from higher throughput.

- Incorporate “Soft” Benefits: While harder to quantify, consider benefits like improved brand reputation due to higher product quality and increased team morale from focusing on more engaging work.

Conclusion

Embracing intelligent automation is no longer a forward-thinking option but a strategic imperative for any manufacturer serious about long-term competitiveness. The move toward AI for Quality Assurance represents a definitive shift from a reactive, cost-driven function to a proactive, value-generating pillar of the operation. This is about embedding intelligence into the very fabric of production. By leveraging sophisticated and practical tools, organizations can achieve unprecedented levels of efficiency and certainty.