The financial and reputational cost of a single defect escaping the factory floor can be catastrophic, leading to recalls, wasted resources, and eroded customer trust. Relying solely on manual inspection introduces a significant, unquantifiable risk into the value chain.

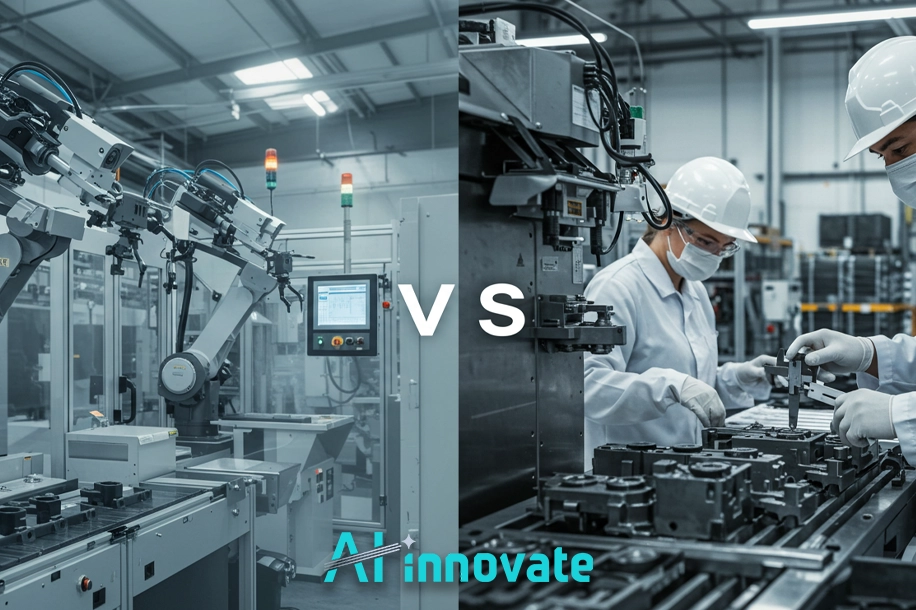

At AI-Innovate, we develop sophisticated AI and machine vision solutions engineered to mitigate this exact risk by delivering exceptional accuracy. This article moves past hypotheticals to deliver a frank analysis of Automated Quality Control vs Manual Inspection, focusing on ROI, error rates, and the quantifiable business case for deploying intelligent systems to protect your brand and bottom line.

Next-Level Quality Control Starts Here

Let AI inspect, analyze, and optimize – faster and smarter than ever.

The Human Factor in Inspection

For decades, the human inspector has been the cornerstone of quality assurance. The unmatched flexibility of the human eye, guided by intuition and experience, allows for the identification of novel or highly irregular defects that a rigidly programmed system might miss.

An experienced operator can assess complex surfaces and make nuanced judgments that are difficult to codify. This adaptive expertise is valuable, forming a baseline for what quality means.

However, this same reliance on human subjectivity is also a source of significant vulnerability, introducing inconsistency and fatigue-driven errors into a process that demands absolute uniformity.

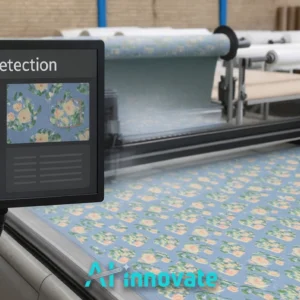

Anatomy of a Digital Inspection

A digital inspection transcends simple photography; it is a sophisticated cognitive process executed at machine speed. At its core, the system captures a high-resolution image, converting the physical product into a dense matrix of pixels.

This digital footprint is then instantly analyzed by an AI model, typically a deep learning neural network that has been rigorously trained on a vast dataset of both conforming and non-conforming examples.

Unlike a human, the model does not “interpret” in a subjective sense. Instead, it performs a complex mathematical analysis, comparing the product’s digital signature against its learned model of perfection.

The result is a purely objective, binary verdict—pass or fail—devoid of fatigue, bias, or inconsistency. This methodical conversion of pixels to a definitive verdict is what enables such high levels of accuracy and data generation.

Read Also: AI-Driven Quality Control – Transforming QC With AI

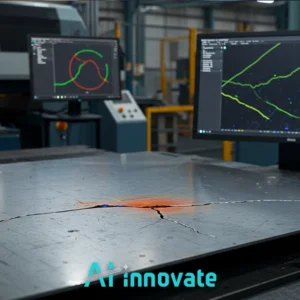

The Threshold of Machine Precision

Automated systems operate on a fundamentally different principle: unwavering, verifiable consistency. By leveraging AI and machine vision, these systems move past the limitations of human biology to deliver a new standard of accuracy.

When we analyze the technical debate of Automated Quality Control vs Manual Inspection, the capabilities of automation become starkly evident. To fully appreciate this shift, consider the core operational advantages these systems bring to the factory floor:

- Perpetual Operation: Automated systems function continuously without degradation in performance, ensuring that the first and last product of a shift are inspected with the exact same level of scrutiny.

- Unwavering Consistency: Every inspection is performed according to identical, pre-defined parameters, eliminating the variability in judgment between different human inspectors and achieving a defect detection accuracy that can exceed 99%.

- High-Speed Throughput: Where a human may require several seconds per piece, automated stations can inspect thousands of units per minute, directly addressing production bottlenecks and scaling seamlessly with demand.

Read Also: Machine Learning in Quality Control – Smarter Inspections

Quantifiable Gaps in Manual Diligence

While the conceptual benefits are clear, the business case becomes compelling when examining the hard data. The differences in performance between the two methods are not minor; they represent a significant gap in operational efficiency, cost, and reliability.

The choice in the Automated Quality Control vs Manual Inspection dilemma directly impacts a company’s bottom line and competitive standing. The following table offers a direct comparison of key performance metrics, compiled from industry data, to illustrate the tangible gaps.

| Metric | Manual Inspection | Automated Inspection |

| Error Rate | 15% – 40% of defects are missed | Less than 1% error rate is achievable |

| Annual Labor Cost | Can exceed $89,000 per inspector | High initial ROI via reduced labor needs |

| Data Traceability | Manual logging; prone to error and difficult to analyze | Comprehensive, real-time data capture for every item |

Operational Synergy of Human and AI

The most advanced approach to quality control is not a complete replacement of human operators but a strategic collaboration between human expertise and machine precision. This hybrid model, often termed “assisted inspection,” creates a powerful synergy.

The goal is to elevate the role of the human inspector from repetitive manual labor to complex decision-making and final validation. This operational model transforms the factory floor, as explored in the following processes.

Redirecting Complexity

In this framework, our AI2Eye system handles the high-volume, repetitive task of scanning every single product for known defect types. Its speed and accuracy ensure comprehensive coverage.

However, when the system identifies a novel or ambiguous anomaly that falls outside its defined parameters, it intelligently flags and routes the item to a human expert for final assessment, ensuring that complex issues receive the nuanced judgment they require.

Human-in-the-Loop Validation

This collaborative process does more than just sort products. The feedback from the human inspector on these complex cases is fed back into the AI model. This “human-in-the-loop” validation continuously refines and improves the system’s intelligence over time. It empowers employees, builds trust in the technology, and creates an ever-smarter quality control ecosystem.

Accelerating Development without Hardware

For the technical teams driving innovation, a significant challenge in the field of Automated Quality Control vs Manual Inspection lies not just in deployment, but in development. Machine learning engineers and R&D specialists are often slowed by their dependency on physical camera hardware for prototyping and testing vision applications.

Our approach directly addresses this critical bottleneck. This is precisely the challenge our AI2Cam virtual camera emulator is designed to solve, providing a software-first environment for development. It unchains innovation from physical constraints in several key ways.

Rapid Prototyping Cycles

With AI2Cam, developers can simulate a wide range of industrial cameras and lighting conditions directly on their computer. This enables them to test and iterate on their detection algorithms almost instantly, dramatically accelerating the prototyping lifecycle without waiting for hardware procurement or setup.

Decoupling Software from Hardware

Engineers can develop and refine the core AI software in parallel with the hardware selection process. This decoupling means that by the time the physical cameras are installed on the production line, the software is already mature, tested, and ready for integration, minimizing project delays.

Flexible Scenario Simulation

AI2Cam allows developers to easily create and test for edge cases and rare defect scenarios that would be difficult, costly, or time-consuming to replicate with physical products. This ensures the final system is more robust and reliable when deployed in the real world.

Activate Your Intelligent Production Line

Moving from traditional inspection to an automated, intelligent system is more than an upgrade—it is a strategic transformation of your production capabilities. It aligns your operations with the demands of modern industry for higher efficiency, reduced waste, and verifiable quality.

This transition begins with a practical assessment of your unique challenges. Contact our experts at AI-Innovate to explore how our AI2Eye and AI2Cam solutions can be deployed to activate a smarter, more resilient production line for your business.

Conclusion

Manual inspection, while historically significant, possesses inherent limitations that cannot be overcome through training alone. The evidence strongly indicates that automated systems offer superior accuracy, speed, and data-driven insights. The most powerful path forward lies in a synergistic combination of human and machine. Investing strategically in the transition from Automated Quality Control vs Manual Inspection is no longer an option, but a competitive necessity for any forward-thinking manufacturer.