A digital twin is a virtual model of a process, product, or service. In manufacturing, the digital twin is a virtual representation of the as-designed, as-built, and as-maintained physical product, augmented by real-time process data and analytics based on accurate configurations of the physical product, production systems, or equipment. This pairing of the virtual and physical worlds, in essence, allows analysis of data and monitoring of systems to head off problems before they even occur, prevent downtime, optimize performance, and even plan for the future by using simulations.

Thus, the digital twin is a bridge between the physical and digital world. While virtual models are conceptual in nature, real-time and operational data is a digital representation of real physical events. CAD models represent the virtual fit, form, and function of the digital twin’s physical counterpart. However, real-time operational and asset data are required to execute analytics applications that define the state and behavior of the performance-based digital twin and allow optimization and process improvement.

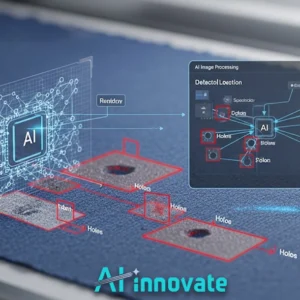

Digital twin includes partial or entire components of the IoT: smart components that use sensors to gather data about real-time status, working condition, or position are integrated with a physical item. The components are connected to a cloud-based system that receives and processes all the data the sensors monitor. This input is analyzed against business and other contextual data.

Today’s advanced virtual simulation technology is an integral component of the digital twin. Comprehensive simulation platforms can simulate and validate the functionality of product design concurrently, enabling the designers to validate their designs as they go. In the context of the digital twin, real-time sensor data can be used to populate simulation applications that then emulate the physical product and enable design improvements. Customers are offered the use of the product/equipment along with complete maintenance and operational optimization based on the predictive/prescriptive capabilities of the digital twin. The manufacturer maintains ownership of the equipment while providing the service of maintenance based on a digital twin as a more manageable and profitable business model.

Digital twins are powerful masterminds to drive innovation and performance, and this aspect makes it very important to businesses. It is equivalent to the most talented product technicians with the most advanced monitoring, analytical, and predictive capabilities at their fingertips, but significantly faster and more accurate. Increasing performance efficiency, decreasing the cost of production, and almost eliminating the probability of error are the immediate advantages of digital twin.