Combating rising operational costs and persistent error rates tied to outdated quality methods is a major industrial challenge. Driving manufacturing efficiency demands automated, reliable systems delivering measurable results. Machine Learning in Quality Control offers a direct technical path to improved operational value by automating high-precision inspection, predicting anomalies, and optimizing processes, securing tangible ROI.

AI-Innovate delivers applied AI solutions engineered for industrial effectiveness. Explore ML’s impact on manufacturing quality, efficiency, and tangible value here.

Upgrade Your Quality Control with Machine Learning

From data to decisions – let ML handle the complexity.

Quality Evolution Milestones

The journey of industrial quality control began with craftsmen individually inspecting finished goods, a methodology tied to the output rate and discernment of a single person. As production scaled, manual spot checks and post-production quality gates became standard.

The subsequent rise of statistical quality control (SQC) marked a shift toward process-oriented thinking. Techniques utilizing control charts (like X-bar and R charts) and acceptance sampling plans helped monitor process variability based on sample measurements from subgroups taken over time.

This offered insights into process stability, signaling ‘out-of-control’ conditions that might indicate a quality issue developing. However, SQC primarily functioned as a reactive diagnostic tool; deviations were flagged after their occurrence in the production flow, requiring investigation into past output to isolate affected batches.

The sheer data volume generated by high-speed, interconnected production lines, combined with the need to detect subtle, complex defect patterns instantly rather than retrospectively, strained the capacity of these statistical methods.

A more dynamic and predictive approach, capable of learning directly from continuous, high-dimensional data streams, particularly through the lens of Machine Learning in Quality Control, became essential to push quality capabilities forward and address complex defect profiles.

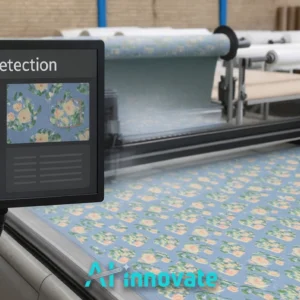

Visual Discrepancy Capture

Automated visual inspection stands as a primary domain where machine learning capabilities significantly advance quality control. Unlike older, rule-based machine vision that struggled with variations or complex textures, ML models, especially deep convolutional neural networks (CNNs), excel at interpreting high-resolution image data from industrial cameras (such as line scan cameras, area scan cameras, or specialized thermal/IR sensors).

Deep Learning for Automated Examination

These advanced vision systems are trained to autonomously assess product characteristics. They identify and classify an extensive range of visual properties and potential flaws, forming the technical foundation of modern defect detection.

Precise Flaw Identification

By analyzing imagery captured on the production line, ML models trained on carefully curated datasets containing diverse examples—even microscopic surface imperfections or intricate assembly errors—can reliably spot deviations. This precision revolutionizes Defect Detection in Manufacturing, including applications from recognizing welding defects in metal fabrication to identifying misprints on packaging.

Real-Time Insights from Visual Data

Integrated systems process visual input with minimal latency, enabling real-time defect analysis. Flagging non-conforming items the instant they are detected allows operators or automated systems to divert flawed products or halt production promptly, minimizing the output of substandard goods.

Systems akin to AI-Innovate’s ai2eye provide this ‘super-powered set of eyes,’ offering automated inspection and the identification of tiny defects that are often missed by manual processes on fast-moving lines.

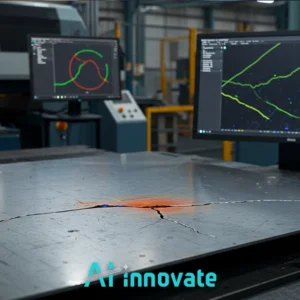

Production Insight Weaving

Beyond just analyzing discrete product images, Machine Learning in Quality Control also empowers manufacturers to glean profound insights from integrating and analyzing vast quantities of multivariate data generated across the production environment—including sensor readings, machine logs, environmental conditions, material properties, and state data from Programmable Logic Controllers (PLCs) or Manufacturing Execution Systems (MES).

ML algorithms trained on these complex streams can uncover subtle correlations that directly influence product quality outcomes, far exceeding manual analytical capabilities. Analyzing these fused datasets enables:

- Identification of previously hidden process variables (e.g., minor temperature fluctuations, slight pressure drops, machine vibrations outside standard deviation) that predict defect occurrence downstream.

- Proactive identification of equipment showing signs of potential degradation (Predictive Maintenance indicators) before it impacts product quality.

- Generation of data-driven recommendations for tuning machine parameters or environmental controls to sustain optimal production conditions.

- Dynamic adaptation of inspection criteria or process parameters based on real-time material characteristics or environmental shifts.

This comprehensive data-driven approach transforms manufacturing quality management, evolving from static controls to dynamic manufacturing process optimization—constantly refining the process based on observed data to prevent faults proactively, not just react to them.

Tangible Outcome Quantification

The strategic adoption of Machine Learning in Quality Control delivers measurable, significant advantages that directly impact operational efficiency and profitability. Quantifiable outcomes demonstrate the tangible value derived from moving beyond traditional approaches. Concrete Benefits Observed:

- Reduced Scrap Rates: Automated, high-precision inspection captures defects early, minimizing waste and lowering material costs associated with failed products and subsequent rework.

- Increased Throughput Speeds: Automated systems inspect products orders of magnitude faster than human inspectors, enabling manufacturers to run lines at higher speeds while ensuring 100% inspection.

- Operational Cost Efficiency: Automation reduces dependence on labor-intensive inspection roles, decreases costs tied to handling customer returns and warranty claims for undetected defects, and minimizes downtime via predictive insights.

- Consistent and Traceable Quality: Algorithmic decision-making is entirely consistent, providing uniform quality assessment irrespective of time or operator. Detailed logs of automated inspections also provide robust traceability.

- Improved Capital Expenditure Utilization: Better control over process variations extends equipment lifespan and optimizes utilization.

These consolidated effects result in a robust return on investment (ROI), allowing manufacturers to redeploy resources previously spent on managing defects or manual inspections toward higher-value activities like innovation or further optimization.

Implementation Journey Stumbles

Successfully deploying ML solutions in industrial quality control requires careful planning and navigating several potential challenges that extend beyond algorithmic development itself.

Data Pipeline Challenges

Gathering, annotating, and managing the massive, diverse datasets needed to train accurate models for tasks like anomaly detection or defect classification presents a significant technical and logistical hurdle. Ensuring data consistency and quality from heterogeneous industrial sensors is complex.

System Integration

Integrating modern ML software platforms with existing, potentially aged or proprietary, industrial automation hardware (sensors, PLCs, robotic arms) and enterprise systems (MES, ERP) demands deep technical understanding of communication protocols and requires careful orchestration to ensure smooth data flow and coordinated operations.

Ongoing Model Validation and Retraining

Deployed ML models require continuous monitoring and periodic retraining. Factors like component wear, slight shifts in raw material properties, or process modifications can lead to ‘model drift,’ degrading performance over time. Establishing processes for regular validation against new data and implementing retraining strategies is essential to maintain accuracy.

Applications of Machine Learning in Quality Control Across Different Industries

Machine Learning in Quality Control is transforming how diverse industries maintain consistency, reduce waste, and drive measurable value through intelligent automation. By adapting to high-dimensional data and learning from production nuances, ML enables real-time, scalable inspection that surpasses traditional methods.

Here’s how various sectors are deploying it effectively:

Automotive Manufacturing

ML-driven visual inspection systems detect micro-defects in paint, welding seams, or assembly alignment. Predictive maintenance models help prevent quality drift due to tool wear or calibration issues.

Pharmaceuticals and Biotech

Ensuring sterility and precision in fill levels, packaging integrity, and surface contamination is critical. Machine Learning in Quality Control is used for particle detection in injectables, label verification, and compliance tracking across batches.

Electronics and Semiconductors

High-resolution defect detection on printed circuit boards (PCBs), soldering joints, and wafer surfaces is powered by CNN-based inspection models. ML also supports anomaly detection in process logs during wafer fabrication.

Food and Beverage

ML models monitor packaging defects, fill level discrepancies, and label placement in real time. Optical systems powered by machine learning also ensure product consistency in color, shape, and texture.

Aerospace and Defense

Critical tolerance inspections, non-destructive testing (NDT), and real-time anomaly detection during composite material production rely heavily on Machine Learning in Quality Control to uphold safety standards.

Across all these industries, Machine Learning in Quality Control isn’t just a technical upgrade—it’s a strategic enabler of reliability, speed, and operational excellence.

Empowering Development Trajectories

For engineering teams tasked with building and refining sophisticated vision-based inspection systems leveraging machine learning, the iterative development process is often encumbered by the necessity of accessing and configuring physical camera setups representative of varied production environments.

Testing machine vision algorithms and ML models requires capturing diverse images, which, when tied to physical hardware, introduces delays related to equipment procurement, setup time, calibration, and coordination across dispersed development teams.

Specialized software tools offer a potent solution by creating a layer of abstraction. Consider the capabilities of a tool like AI-Innovate’s ai2cam:

- It functions as a software-based ‘camera emulator,’ allowing developers to simulate outputs from numerous industrial camera models.

- Diverse imaging conditions—variations in resolution, noise levels, focus, or lighting (e.g., simulating different light sources or reflections)—can be reproduced digitally.

- Developers can test their algorithms and models against synthetic or recorded data simulating realistic conditions without needing the physical camera present.

- This simulation significantly accelerates the iterative process of tuning models for precision and robustness, facilitating AI for quality assurance development.

- It bypasses delays and costs associated with physical hardware management, empowering technical teams with increased flexibility and speed in innovation.

Bridging Practice and Potential

Bringing the immense potential of machine learning from concept into a tangible, impactful application within industrial quality control is a journey demanding practical solutions, not just theoretical insights.

Manufacturers seeking to fully leverage what ML offers need partners who understand the intricacies of both advanced AI models and the realities of factory floor environments. That is precisely the gap we at AI-Innovate are dedicated to bridging.

We specialize in developing and deploying sophisticated software solutions—melding the power of AI, machine learning, and computer vision—specifically engineered to tackle the most critical, real-world quality challenges you face.

From delivering high-precision, real-time defect inspection on complex materials, leveraging techniques vital for effective quality control that capabilities like our ai2eye system exemplify, to providing developers with innovative tools such as our ai2cam virtual camera to accelerate the crucial, often hardware-dependent phase of testing machine vision algorithms, we build the technical infrastructure that enables putting machine learning in production.

Our mission is fundamentally centered on empowering your industrial operations, translating technical prowess into tangible operational advantages and robust business outcomes. To understand firsthand how AI-Innovate’s tailored solutions and practical approach can enhance your operational quality and accelerate your strategic shift towards advanced quality management, we invite you to explore our full suite of offerings. Discover the difference AI-Innovate brings to the intersection of AI and industrial excellence.

Conclusion

The integration of Machine Learning in Quality Control represents a pivotal advancement, fundamentally altering industrial paradigms. Moving beyond conventional limits, ML provides granular insight, unprecedented inspection accuracy, and critical process optimization capabilities. While implementation involves navigable challenges, the documented gains in efficiency, waste reduction, and overall quality consistency underscore ML’s essential role. Adopting these sophisticated techniques is no longer optional but fundamental for manufacturers aiming to secure a competitive advantage and achieve operational excellence in complex global markets.