The human eye, for all its adaptability, has non-negotiable physical limits in resolution, spectral range, and consistency. In applications where defects are measured in microns and inspection cycle times in milliseconds, these limits become a critical point of failure. The core of the Machine Vision vs Human Inspection analysis rests on these physical realities of performance under pressure.

Our mission at AI-Innovate is to deliver systems that operate with unwavering precision far beyond these human thresholds. This article delves into the granular, evidence-based metrics of accuracy and reliability, presenting a technical comparison for engineers and QA leaders.

Let Vision Systems Lead Inspection

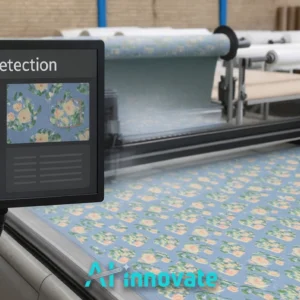

Precise, automated defect detection at scale.

The Spectrum of Human Vigilance

For decades, human inspectors have been the cornerstone of quality assurance. Their cognitive flexibility and intuitive understanding allow them to identify novel or unexpected defects that fall outside predefined categories—a nuanced capability that is difficult to program.

An experienced inspector can assess contextual subtlety, such as determining if a minor cosmetic blemish is acceptable on one part but constitutes a critical failure on another. However, this expertise is coupled with inherent limitations that become especially apparent in high-volume, repetitive industrial settings. To provide a clearer picture, consider these practical constraints:

- Fatigue and Inconsistency: Human concentration naturally wanes over a long shift, leading to inconsistent performance and a higher probability of error.

- Subjectivity in Judgment: What one inspector flags as a defect, another might pass. This variability can lead to inconsistent product quality, impacting customer satisfaction.

- Scalability Issues: In high-speed production environments, it is often impractical and cost-prohibitive to deploy a large enough team of inspectors to check every single item thoroughly.

The Mechanics of Automated Scrutiny

Machine vision systems approach quality control from a purely data-driven perspective. These systems are not merely cameras; they are integrated solutions designed for a singular purpose: objective, relentless, and high-speed analysis.

Understanding how they function reveals the core of their advantage in the Machine Vision vs Human Inspection comparison. Let’s delve into their key functional aspects.

Core Components

At its heart, a machine vision system is a synergy of hardware. A high-resolution industrial camera captures the image, specialized lighting illuminates the subject to eliminate shadows and highlight features of interest, and a processing unit runs the complex algorithms needed for analysis. Each component is optimized to work in concert, ensuring that the acquired image data is as clear and information-rich as possible.

Operational Principles

Once an image is captured, the software takes over. The system can perform inspections at speeds far exceeding human capability, in some cases processing up to 20 items per second. Using sophisticated algorithms, it can identify defects with microscopic precision, spotting flaws as small as 0.02 mm² that are functionally invisible to the human eye. Crucially, these systems operate with unwavering consistency, 24/7, without any degradation in performance, guaranteeing a uniform quality standard across all production batches.

A Direct Comparison of Core Benchmarks

To make an informed decision between these two methodologies, a direct, evidence-based comparison is essential. The following table breaks down their performance across five critical benchmarks, drawing upon industry data and technical reports to provide a clear, side-by-side view.

| Benchmark | Human Inspection | Machine Vision |

| Accuracy | Variable, typically averages between 80-85% under optimal conditions and declines with fatigue. | Consistently high, can reach over 98% accuracy for trained defect types |

| Speed | Limited by human cognitive and physical speed; averages a few items per minute. | Extremely high; capable of inspecting multiple items per second. |

| Consistency | Inherently variable and subjective; depends on individual skill, alertness, and time of day. | Near-perfect repeatability; every item is inspected using the exact same criteria, 24/7. |

| Long-Term Cost (ROI) | Low initial setup cost but high, recurring labor costs that scale with production volume. | Higher initial investment but delivers strong ROI by reducing waste, recalls, and labor costs. |

| Data Collection | Limited to manual logs; provides little to no data for broader process analysis. | Automatically captures and logs detailed data on every item, enabling deep process analytics. |

This data-driven summary clearly illustrates the operational differences. While the nuance of human judgment holds value, the metrics essential for modern, scaled manufacturing—speed, consistency, and data generation—are domains where automated systems excel. The debate over Machine Vision vs Human Inspection often boils down to these measurable outcomes.

Read Also: Automated Quality Control vs Manual Inspection

Data-Driven Process Optimization

A significant advantage of automated inspection, and one that is often overlooked, is its ability to transform quality control from a simple pass/fail gate into an engine for process intelligence. Systems like our AI2Eye are designed to do more than just find flaws; they capture data that can be used to optimize the entire production line.

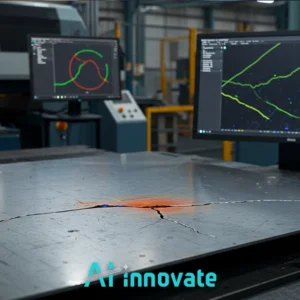

From Defect Finding to Root Cause Analysis

Because an AI vision system logs the precise type and location of every defect, patterns begin to emerge. A recurring scratch at the same spot on multiple products can be traced back to a specific misaligned machine or a piece of faulty equipment upstream. This shifts the focus from reactively catching defects to proactively fixing the source of the problem, dramatically reducing waste and rework.

Read Also: Machine Vision for Defect Detection – Boost Product Quality

Unlocking Predictive Quality Insights

The massive dataset generated by a vision system is a goldmine for predictive analytics. By analyzing trends over time, manufacturers can identify subtle degradations in equipment performance before they lead to catastrophic failures. This enables a shift toward predictive maintenance, further increasing uptime and overall equipment effectiveness (OEE).

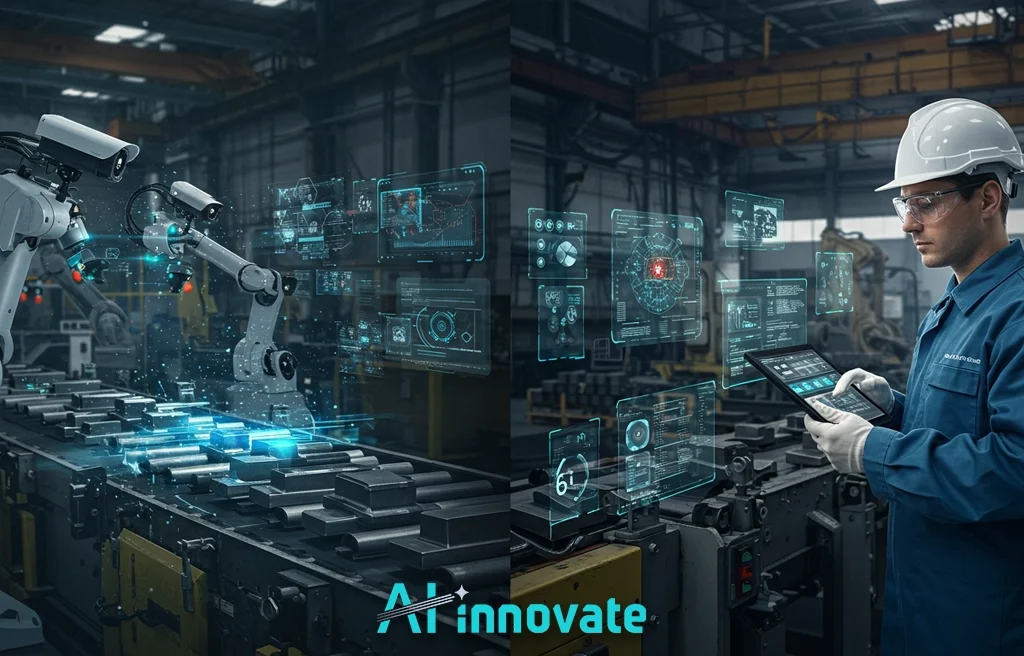

Toward a Hybrid Inspection Model

The most pragmatic and powerful approach to quality control is not an “either/or” choice but a collaborative, hybrid model. In this framework, automated systems and human experts work in synergy, each leveraging their unique strengths.

This vision moves past the confrontational framing of Machine Vision vs Human Inspection and toward a functional partnership. In this model, machine vision systems act as tireless, front-line screeners, handling the high-volume, repetitive tasks with speed and precision.

They flag potential defects and handle 100% of the routine inspections. This frees up skilled human inspectors to focus on higher-value activities: analyzing the data provided by the AI, making judgment calls on complex or ambiguous defects, managing new product introductions, and driving process improvement initiatives based on the system’s insights.

Read Also: Automated Visual Inspection – Your Path to Zero Errors

Accelerate Your Vision Development

You now have the blueprint. The next step is not just to choose a technology but to actively engineer a new standard of quality for your organization. This is where strategic vision meets practical application, and we provide the tools for this transformation.

If you are an Industrial Leader, your mandate is to build more resilient and efficient operations. Your tool is AI2Eye. Let us show you how this system will become the intelligent cornerstone of your quality assurance.

If you are a Technical Developer, your mandate is to innovate without limits. Your tool is AI2Cam. Break free from the constraints of physical hardware and accelerate your development cycle. Contact our solution architects to begin building.

Conclusion

Ultimately, the debate over Machine Vision vs Human Inspection finds its answer not in a victor, but in a powerful synthesis. The future of elite quality control lies in augmenting human expertise with the precision, speed, and data-gathering power of AI. Adopting this hybrid model is a strategic investment in creating more efficient, resilient, and intelligent manufacturing operations.