In modern industrial environments, the pursuit of operational excellence is relentless. Traditional process monitoring, reliant on manual checks and lagging indicators, is increasingly inadequate to meet the complex demands of high-velocity manufacturing. At AI-Innovate, we bridge this gap by architecting intelligent systems that redefine production oversight.

This article moves beyond theoretical discussions to provide a technical and actionable guide. We will explore the critical components of implementing robust AI for Process Monitoring, detailing the strategic frameworks and technologies that empower industrial leaders and technical developers to achieve unprecedented efficiency and quality in their operations.

Real-Time Insights with AI Monitoring

Track, detect, and act before downtime hits.

Imperatives for Advanced Process Oversight

The shift from manual to automated process oversight is no longer a strategic choice but a competitive necessity. The financial drain from undetected production flaws, such as micro-fractures in metal components or inconsistencies in textile weaves, extends far beyond material waste.

It encompasses the high operational costs of rework, production delays, and the erosion of brand reputation due to quality escapes. Manual inspection, constrained by human subjectivity and fatigue, cannot deliver the consistency required for today’s precision manufacturing.

As one industry analysis highlights, “In high-throughput environments, even a 1% error rate can translate into thousands of defective units, representing a significant impact on profitability.” This underscores the urgent need for a more sophisticated, data-driven approach to ensure every product conforms to exact specifications.

Data Fidelity in Algorithmic Monitoring

The effectiveness of any algorithmic oversight system is fundamentally anchored to the quality of its input data. The principle of ‘garbage in, garbage out’ has never been more relevant. An AI model, no matter how sophisticated, will produce unreliable insights if fed with inconsistent, incomplete, or inaccurate data.

This concept of data fidelity—the trustworthiness of data in its operational context—is the true bedrock of successful AI for Process Monitoring. Achieving it requires a disciplined approach to the entire data lifecycle. To better understand the pillars supporting data fidelity, consider the following critical factors:

- Systematic Sensor Calibration: Ensuring that all measurement instruments are meticulously and regularly calibrated to maintain accuracy and eliminate drift over time.

- Consistent Data Collection Protocols: Establishing and enforcing standardized procedures for data acquisition to guarantee uniformity across different shifts, machines, and production runs.

- Accurate and Contextual Anomaly Labeling: Providing clean, well-documented, and context-rich labels for training data, which is essential for supervised machine learning models to learn effectively.

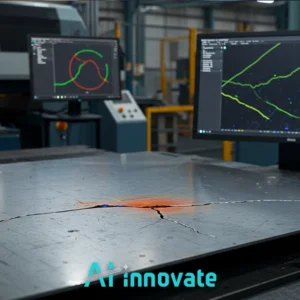

From Anomaly Detection to Root Cause Analysis

Early AI systems in manufacturing were primarily focused on a binary task: identifying anomalies. A system could flag a product as defective, but it couldn’t explain why. Today, the technology has evolved into a far more powerful diagnostic tool.

Modern AI-driven platforms move beyond simple defect detection to perform sophisticated root cause analysis. By analyzing vast datasets from multiple points in the production line, these systems can identify subtle patterns and correlations that precede a fault.

This capability represents a paradigm shift from reactive problem-fixing to proactive process optimization. For instance, the system may correlate a minute temperature fluctuation in an extruder with the appearance of surface blemishes on a polymer sheet ten minutes later—an insight impossible to glean through manual observation alone.

Read Also: Defect Detection in Manufacturing – AI-Powered Quality

Machine Vision Process Interrogation

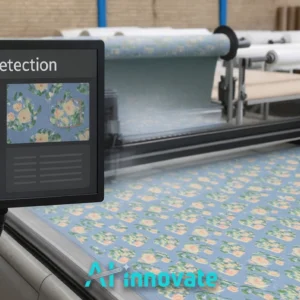

At the core of modern industrial automation is the ability to not just see, but to understand. This is the domain of machine vision, a field that, when coupled with AI, becomes a powerful tool for process interrogation.

It actively scrutinizes every step of production, searching for deviations from the optimal standard. This technology is essential for industries where visual perfection is paramount, from flawless finishes in metal defect detection to uniform color in textiles. For Operations and QA Managers looking to implement robust AI-driven quality control, the challenge lies in deploying a system that is both powerful and seamlessly integrated.

AI2Eye: Real-Time Quality Assurance in Action

At AI-Innovate, our AI2Eye system is engineered to meet this challenge head-on. It serves as an intelligent set of eyes on your production line, enabling a level of precision that transcends human capability. Consider its direct benefits for your operations:

- Real-time Defect Analysis: Instantly identifies surface defects, assembly errors, and other imperfections as they occur, allowing for immediate corrective action.

- Waste and Rework Reduction: By catching flaws early, AI2Eye minimizes scrap and the costly process of manual re-inspection and rework.

- Process Optimization Insights: Moves beyond mere inspection to analyze workflow patterns, identify systemic bottlenecks, and provide data-backed recommendations for improvement.

Harness the power of AI2Eye to transform your quality control from a cost center into a driver of competitive advantage.

Navigating Prototyping and Hardware Barriers

For the R&D specialists and ML engineers driving innovation, the development cycle for new machine vision applications is often hampered by a significant bottleneck: hardware dependency.

Procuring, setting up, and reconfiguring physical cameras and lighting for diverse testing scenarios is both costly and time-consuming. This hardware-centric approach creates project delays, stifles experimentation, and limits the ability of remote teams to collaborate effectively.

The practical solution to this widespread problem is to decouple software development from physical hardware constraints. A core objective for any advanced system of AI for Process Monitoring must therefore be the removal of such barriers.

AI2Cam: Accelerating Development with Virtual Cameras

To address this critical need, AI-Innovate developed AI2Cam, a sophisticated camera emulation tool designed for developers. It empowers technical teams to accelerate their innovation cycle significantly. Here’s how AI2Cam removes common development obstacles:

- Accelerated Prototyping: Simulate a vast array of industrial cameras, resolutions, and environmental conditions directly on a computer, enabling rapid testing and iteration.

- Reduced Development Costs: Eliminates the need to invest in expensive physical camera hardware during the prototyping and testing phases.

- Enhanced Collaboration and Flexibility: Allows distributed teams to work on the same virtual setup, fostering seamless remote collaboration and innovation.

With AI2Cam, you can empower your engineers to build and refine the next generation of machine vision solutions faster and more affordably.

Strategic Implementation Frameworks

Successfully deploying an AI for Process Monitoring solution is not merely a technical task; it is a strategic initiative that requires a clear and structured plan. Adopting an ad-hoc approach often leads to pilot projects that fail to scale or deliver the expected ROI.

A disciplined, phased framework is essential to align the technology with specific business objectives and ensure a smooth integration into existing workflows. Drawing from established methodologies like Lean Six Sigma and best practices in technology adoption, we recommend a clear roadmap for implementation.

The following steps outline a proven path to success:

- Define a Focused Business Case: Start by identifying a high-impact problem. Clearly define the Key Performance Indicators (KPIs) you aim to improve, such as reducing a specific type of defect by X% or increasing throughput by Y%.

- Assess Data Infrastructure and Fidelity: Evaluate the quality, accessibility, and consistency of your current data sources. Ensure that sensor data is reliable and that a mechanism for accurate labeling is in place.

- Execute a Controlled Pilot Project: Select a single production line or process for the initial deployment. This allows you to test the solution in a contained environment, measure its impact against the predefined KPIs, and build internal expertise.

- Monitor, Refine, and Scale: Continuously track the performance of the AI model. Use the insights generated to further refine the process and, once proven, develop a phased rollout plan for wider implementation across the facility.

Quantifying Operational and Financial Gains

Ultimately, the adoption of any new technology in an industrial setting is judged by its ability to deliver measurable returns. The implementation of AI for Process Monitoring translates directly into tangible operational and financial improvements that resonate at the executive level.

The gains move far beyond abstract concepts of “efficiency,” providing quantifiable data on core business drivers. This is especially true in areas like machine learning for manufacturing process optimization, where incremental improvements aggregate into significant financial impact. The transition is stark when viewed through key performance metrics, as the following table illustrates:

| Metric | Traditional Monitoring | AI-Powered Oversight |

| Defect Detection Rate | 70-85% (Human) | >99.5% (Automated) |

| Scrap/Rework Reduction | Baseline | 20-50% Reduction |

| Production Downtime | Reactive (Hours) | Predictive (Minutes) |

| Throughput (UPH) | Baseline | 5-15% Increase |

These figures demonstrate a clear and compelling business case. By leveraging AI to optimize quality and efficiency, organizations can unlock substantial value, turning their production data into a strategic asset that drives profitability and market leadership.

The implementation of effective AI for Process Monitoring is thus not just a technological upgrade but a fundamental investment in the financial health of the enterprise.

Conclusion

The transition to intelligent industrial oversight represents a definitive step forward in manufacturing. From enhancing data fidelity to interrogating production lines with machine vision and dismantling development barriers with virtual tools, AI for Process Monitoring offers a comprehensive solution to longstanding challenges. It equips both industrial leaders and technical developers with the power to drive measurable improvements in quality, efficiency, and innovation. At AI-Innovate, we are committed to delivering these practical, powerful solutions that empower our partners to thrive.