The central paradox of automating quality control presents a formidable barrier for many companies. To train an effective AI model, you theoretically need a vast and diverse library of the very flaws your efficient process is designed to eliminate. This frustrating catch-22 often leads to stalled pilot projects and the perception that viable Surface Defect Detection Deep Learning is an unattainable goal without massive datasets.

At AI-Innovate, we were founded to solve precisely these kinds of deeply-rooted industrial challenges. This article breaks down that paradox, revealing the modern techniques that turn data scarcity from a project-killing obstacle into a strategic advantage.

The Material Cost of Human Error

The reliance on manual inspection for quality control has long been the industry standard, but it carries inherent and significant costs. The process is fundamentally limited by human endurance and subjectivity.

Over a long shift, inspector fatigue naturally leads to diminished accuracy, allowing subtle but critical defects to pass unnoticed. This inconsistency translates directly into material waste, customer returns, and potential damage to brand reputation. Furthermore, the human eye, despite its capabilities, struggles to reliably detect micro-defects or imperfections on complex, reflective, or patterned surfaces.

Beyond the direct costs of scrap and rework, the operational overhead of maintaining a large team of manual inspectors is substantial. Training, managing, and scaling this workforce to meet fluctuating production demands introduces significant inefficiencies.

In high-stakes industries like automotive or aerospace, where a single missed flaw can have catastrophic consequences, the limitations of human inspection are not just a matter of cost but of critical safety.

A case study in the steel industry revealed that even highly trained inspectors could miss up to 20% of surface abnormalities during high-speed production runs, a figure that was reduced to less than 1% with an automated system. This reality makes a compelling case for a more robust, consistent, and scalable solution.

Algorithmic Eyes on the Production Line

The transition from manual inspection to automated systems marks a pivotal evolution in quality control. At its core, this shift is powered by algorithms that function as tireless, hyper-aware eyes on the production line.

Unlike human inspectors, these systems do not experience fatigue or a lapse in concentration. They are designed to perform with unwavering consistency, 24/7, scrutinizing every product with the same high degree of precision from the first unit of the day to the last.

This is where the true power of Surface Defect Detection Deep Learning begins to unfold, providing a scalable and reliable alternative. These algorithmic systems are trained on vast datasets of images, learning to distinguish between a perfect product and one with any number of flaws, often on a microscopic level.

They can identify complex patterns, textures, and subtle variations in color or topography that are virtually invisible to the human eye. This capability allows manufacturers to move beyond simply catching obvious errors.

It empowers them to identify emerging issues in the production process itself, long before they result in significant waste. By analyzing the types and frequencies of defects, the system provides actionable data, turning quality control into a proactive tool for process optimization and continuous improvement.

Core Models for Pixel-Perfect Scrutiny

To achieve this level of precision, a range of specialized deep learning architectures has been developed, each tailored for specific industrial challenges. Understanding these core models is key for any technical team looking to implement or refine an automated inspection system.

The choice of model directly impacts the system’s speed, accuracy, and its ability to handle different types of defects. To help you better understand their practical applications, let’s explore the dominant model families:

YOLO and Single-Stage Detectors

You Only Look Once (YOLO) and similar single-stage models are built for speed. They treat defect detection as a single regression problem, simultaneously predicting bounding boxes and class probabilities in one pass.

- Strengths: Extremely fast, making them ideal for real-time inspection on high-speed production lines, such as in metal rolling or packaging.

- Best Use Case: When the primary requirement is identifying the presence and location of defects instantly, and slight inaccuracies in bounding box precision are acceptable.

Faster R-CNN and Two-Stage Detectors

This family of models, including Mask R-CNN, operates in two stages. First, they identify regions of interest (RoIs) where a defect might be present, and then they perform detailed classification and bounding-box refinement on these regions.

- Strengths: Offers higher accuracy, particularly for small or complex defects. Mask R-CNN extends this by providing pixel-level segmentation, precisely outlining the defect’s shape.

- Best Use Case: For high-value products in aerospace or electronics, where precise measurement and analysis of the defect’s geometry are critical.

Read Also: Defect Analysis Techniques – From Root Cause to AI Precision

Autoencoders for Anomaly Detection

Autoencoders are unsupervised learning models trained to reconstruct “normal” or defect-free input images. When a product with a flaw is introduced, the model fails to reconstruct it accurately, and the resulting high “reconstruction error” flags the anomaly.

- Strengths: Does not require a large dataset of pre-labeled defects. It only needs to learn what a good product looks like, which is often much easier to source.

- Best Use Case: In scenarios with rare or unpredictable defects, or in the early stages of a product lifecycle where defect data is scarce.

From Steel Mills to Silicon Wafers

The theoretical power of Surface Defect Detection Deep Learning is best understood through its successful implementation across diverse industrial environments. These real-world applications demonstrate the technology’s adaptability and its tangible impact on quality and efficiency.

By examining how different industries have tackled their unique challenges, we can see a clear pattern of success, for instance:

Automotive Sector Applications

Manufacturers of high-gloss painted automotive parts face the challenge of detecting subtle surface flaws like “orange peel” or microscopic scratches. A case study on crown wheel inspection for the vehicle manufacturer Scania demonstrated that a YOLOv8 model, trained with as few as 20 well-prepared images, could achieve near-perfect accuracy in identifying specific manufacturing flaws, proving the power of targeted data preparation.

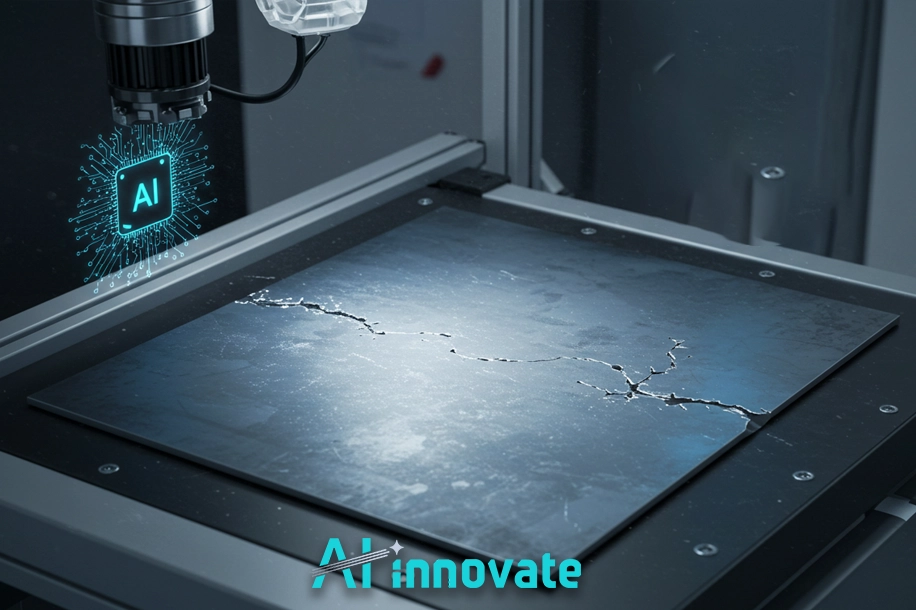

Steel and Metal Production

In the steel industry, high-speed production lines require immediate detection of various defects like pitting, scratches, and scale. Patented systems now use multi-stream CNNs that can simultaneously analyze the entire surface of a steel strip in real-time, classifying different types of defects and routing the data to process control systems to prevent further flawed output.

Electronics and Semiconductor Manufacturing

The production of printed circuit boards (PCBs) and silicon wafers operates on a microscopic scale, where even the smallest foreign particle can render a component useless. Here, Autoencoder models are widely used for anomaly detection.

By training the system on thousands of images of perfect PCBs, it can instantly flag any deviation, from a misplaced solder point to a minuscule crack in the substrate.

Scarcity and Imbalance in Defect Data

Despite its proven success, implementing a robust Surface Defect Detection Deep Learning system is not without its challenges. The most significant hurdles are often related to data, specifically the scarcity of defect samples and the inherent imbalance in industrial datasets.

In a well-run defect detection in manufacturing process, defects are the exception, not the rule. This creates a scenario where a model might be trained on thousands of images of “normal” products for every one image of a specific flaw, leading to a biased system that performs poorly in practice.

Compounding this problem is the difficulty of collecting a comprehensive library of all possible defects. Some flaws may occur so rarely that capturing enough examples to train a supervised model is logistically impossible.

Furthermore, new, unanticipated types of defects can emerge at any time due to changes in raw materials or machine wear. Relying solely on a library of known defects leaves a system vulnerable to the unknown, undermining its core purpose of ensuring comprehensive quality control. These data-centric challenges require a more sophisticated approach than simply collecting more images.

Bridging the Data Gap with Simulation

The most effective solution to the challenges of data scarcity and imbalance lies in simulation and synthetic data generation. Instead of waiting for defects to occur naturally, we can create them virtually.

This approach gives developers complete control over the training process, allowing them to generate vast, perfectly balanced datasets that cover every conceivable defect type, under a multitude of lighting and environmental conditions. This is where tools specifically designed for this purpose become invaluable for both developers and industrial leaders.

This is precisely the problem AI-Innovate addresses. To accelerate this process, we offer a powerful suite of tools:

- ai2cam: A virtual camera emulator designed for developers. It allows your R&D and machine learning teams to rapidly prototype, test, and validate vision systems without any physical hardware. By simulating various cameras and conditions, ai2cam decouples software development from hardware dependency, drastically reducing project timelines and costs.

- ai2eye: Our end-to-end quality control system for the factory floor. It integrates seamlessly into production lines, using its pre-trained models to deliver real-time defect detection and process optimization. For QA Managers and Operations Directors, ai2eye is the practical, ROI-focused application of this powerful technology, reducing waste and boosting efficiency from day one.

Read Also: Machine Vision for Defect Detection – Boost Product Quality

The Next Frontier in Automated Quality

The field of automated quality control continues to advance at a rapid pace. The next frontier is moving beyond 2D image analysis into more holistic inspection methods. Future systems will increasingly rely on 3D Data Fusion, combining traditional camera imagery with 3D scanning to understand not just the surface of a product, but also its geometry and depth.

This allows for the detection of subtle warping or dimensional inaccuracies that are invisible in a 2D plane. Simultaneously, we are seeing the rise of Self-Supervised Systems. These intelligent models are designed to learn and improve over time without continuous human intervention.

By analyzing the stream of production data, they can identify new patterns and adapt to changes in the manufacturing process, effectively “teaching themselves” to spot new types of defects as they emerge. This evolution will make quality control systems more autonomous, robust, and truly integrated into the smart factory ecosystem.

Conclusion

The integration of deep learning into surface defect detection is a proven, transformative force in modern manufacturing. It addresses the fundamental limitations of manual inspection, delivering unparalleled accuracy, consistency, and a wealth of data for process optimization. While data challenges exist, innovative tools and simulation techniques have made these systems more accessible and practical than ever. AI-Innovate is committed to delivering these advanced capabilities through both development tools like ai2cam and turnkey solutions like ai2eye, empowering companies to enhance quality and drive efficiency.