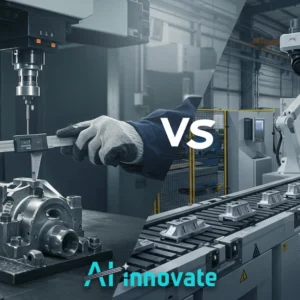

Every defective product that leaves a factory represents a failure—a failure of process, of oversight, and of technology. Manual inspection, constrained by human limitations in speed and consistency, is often the weakest link in the quality chain. This gap is where costly errors and brand damage originate.

AI-Innovate was founded to close this gap with intelligent, practical vision solutions. This article directly addresses the inherent flaws of manual oversight and provides a detailed exploration of Automated Visual inspection as the definitive solution, detailing the technology, applications, and strategies required for achieving zero-defect manufacturing.

Automated , Accurate , Always-On

Replace human fatigue with 24/7 AI inspection.

Core Principles of Automated Inspection

At its heart, an Automated Visual Inspection system digitizes and scales the process of human sight, executing its task with superior speed and consistency. The entire operation, from capturing an image to rendering a final verdict, is a systematic and near-instantaneous process.

To truly understand its power, it’s essential to break down its operational sequence into its fundamental components. This workflow consists of four distinct, sequential stages that work in concert:

- Image Capture: The process begins when high-resolution industrial cameras or sensors capture detailed images of a product or component, typically as it moves along a production line. Proper lighting is crucial at this stage to illuminate defects without creating shadows or glare.

- Image Processing: Sophisticated algorithms then process the captured image. This is not merely about seeing a picture, but computationally analyzing it to enhance features, identify patterns, recognize shapes, and segment distinct regions of interest.

- Comparison: The processed digital image is meticulously compared against a predefined standard or a “golden reference”—a digital model of a perfect product. This comparison checks for any deviations, from minute surface scratches to significant dimensional inaccuracies.

- Decision-Making: Based on the outcome of the comparison, the system makes a binary decision in real-time. The product either meets the quality threshold and passes, or it is flagged for rejection, rework, or further analysis. This immediate feedback loop is what makes the system so effective in a high-volume setting.

The Sensory Spectrum in Visual Inspection

The effectiveness of any visual inspection system is fundamentally dependent on the quality of its input, which begins with the specialized cameras and sensors that serve as its eyes. The choice of sensor is not a one-size-fits-all decision;

it is dictated by the specific nature of the product, the types of defects being targeted, and the unique conditions of the factory floor. Let’s explore some of the key imaging technologies that form the sensory backbone of modern AVI:

Infrared (Thermal) Cameras

These cameras detect temperature variations instead of visible light, making them invaluable for identifying issues that are invisible to the naked eye. By capturing an object’s heat signature, they can pinpoint faulty components that are overheating or imperfections in packaging seals.

3D Cameras and Depth Sensors

Moving beyond a flat, two-dimensional view, 3D cameras create a complete topographical map of a product’s surface. This allows the system to measure not just length and width, but also depth, contour, and volume, making it essential for verifying the precise shape and dimensions of complex mechanical parts.

Hyperspectral Cameras

Hyperspectral imaging captures data across hundreds of narrow spectral bands, far beyond the red, green, and blue receptors of human vision. This technology can identify materials based on their unique spectral signature, a capability used in agriculture to detect crop disease or in food processing to identify foreign contaminants.

Laser Sensors

For applications requiring extreme precision, laser sensors provide highly accurate dimensional measurements. They are used to measure profiles, verify the alignment of components, and ensure that machined parts meet exacting tolerances.

| Sensor Type | Primary Function | Key Industrial Application |

| Infrared (Thermal) | Detects temperature variations | Electronics (overheating circuits), Packaging (seal integrity) |

| 3D & Depth Sensors | Measures shape, dimension, and volume | Automotive (body panel fit), Aerospace (component verification) |

| Hyperspectral | Identifies materials by spectral signature | Agriculture (crop health), Food Safety (spoilage detection) |

| Laser Sensors | Provides high-precision dimensional data | Manufacturing (part measurement), Robotics (positional guidance) |

From Programmed Logic to Adaptive Learning

The traditional approach to automated inspection, often known as Automated Optical Inspection (AOI), historically relied on rigid, rule-based systems. These systems were programmed with a fixed set of parameters to define a defect—for example, any scratch longer than 2mm was a flaw.

While effective in highly controlled environments, this method proved brittle. It struggled to adapt to natural variations in texture, lighting fluctuations, or the introduction of new, undefined defects, often resulting in high rates of false positives.

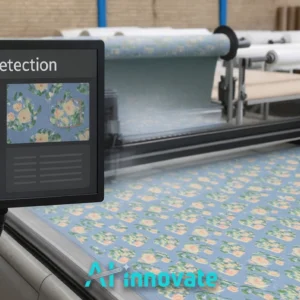

A more advanced paradigm, AI-based automated visual inspection, transcends these limitations by incorporating machine learning. Instead of being explicitly programmed, the system learns to identify defects from a “defect library” of example images.

This adaptive learning approach allows the system to distinguish between acceptable cosmetic variations and genuine functional flaws with a level of nuance that mirrors, and often exceeds, human judgment. The benefits of this modern approach are transformative:

- Superior Defect Detection: AI models excel at identifying complex and subtle defects that are difficult to define with simple rules, leading to higher accuracy and fewer missed flaws.

- Reduced False Positives: The system learns to tolerate acceptable process variability, significantly reducing the number of good products that are incorrectly rejected.

- Scalability and Adaptability: An AI system can be continuously retrained and updated with new data, allowing it to adapt to new product lines or evolving defect classifications without needing a complete reprogramming.

Read Also: Defect Detection in Manufacturing – AI-Powered Quality

Generative AI: Human-in-the-Loop Defect Synthesis

The next leap for Automated Visual Inspection is not just detecting defects, it is manufacturing them in a virtual space before they ever exist in reality. Generative AI now enables the creation of hyper-realistic defect images, from hairline fractures to complex structural distortions, without depending solely on rare faulty parts. When guided by seasoned quality engineers in a human-in-the-loop process, these synthetic defects carry both the precision of machine-generated detail and the nuance of human judgment.

This approach directly addresses one of the most persistent challenges in Automated Visual Inspection: the scarcity of defect data in high-quality manufacturing. By simulating even rare, safety-critical anomalies at scale, teams can build balanced, high-diversity training datasets without halting production or risking damage to actual components.

With synthetic defect libraries in place, inspection systems can be retrained the moment a new product variant or manufacturing method is introduced. Instead of waiting months to gather real-world defect samples, engineers can anticipate potential failure modes, generate thousands of examples overnight, and push updated models into production almost immediately.

In this way, Automated Visual Inspection shifts from a reactive checkpoint to a forward-looking design and process control tool, catching the flaws of tomorrow before they ever have a chance to leave the factory floor.

High-Stakes Industrial Applications

The true value of automated visual inspection is most evident in industries where the margin for error is virtually zero. In these high-stakes environments, the technology is not a luxury but a core component of quality assurance and regulatory compliance.

- Pharmaceuticals: In pharmaceutical manufacturing, the sterility and integrity of products like vials, syringes, and ampules are paramount. AVI systems are deployed to scan for minuscule particulate matter, cracks in the glass, or improper seals that could compromise patient safety, all while operating at speeds that manual inspection could never achieve.

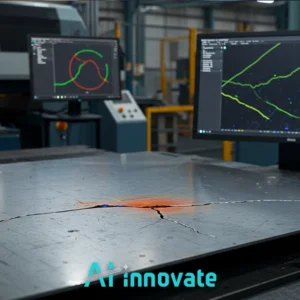

- Aerospace & Automotive: For industries that build complex machines like airplanes and cars, structural integrity is a matter of life and death. Here, 3D and laser-based inspection systems verify the precise dimensions of millions of components, from engine parts to body panels, ensuring every piece conforms to exact design specifications.

- Electronics: The production of semiconductor wafers and printed circuit boards (PCBs) involves features measured in micrometers. AVI systems are indispensable for detecting flaws like broken traces, misplaced components, or soldering defects that are too small for the human eye to consistently see.

Operational Realities and Implementation Hurdles

While the benefits are clear, integrating an automated visual inspection system is a significant undertaking that requires careful planning. Success is not guaranteed by simply purchasing a camera and software; it depends on addressing several key operational realities. Prospective adopters should be prepared for the following hurdles:

- Initial Investment: The combination of specialized hardware (cameras, lighting, optics) and sophisticated software represents a considerable upfront capital expenditure.

- Data Quality and Quantity: AI-based systems are data-hungry. Acquiring a large, accurately labeled dataset of both good and bad products to train the model can be a time-consuming and resource-intensive process.

- Lighting and Environmental Control: The performance of any vision system is highly sensitive to lighting. Developing a robust solution requires controlling ambient light and engineering a setup that consistently illuminates the features of interest without creating confounding shadows or reflections.

- System Maintenance and Calibration: Like any high-precision instrument, an AVI system requires ongoing maintenance and periodic recalibration to ensure its accuracy and reliability over time.

Accelerating Innovation with Camera Emulation

The wide variety of specialized sensors required for different inspection tasks presents a major bottleneck for the engineers and R&D specialists tasked with developing new vision applications. Acquiring, setting up, and reconfiguring diverse and expensive physical camera hardware for prototyping is a slow, costly, and inefficient process. It can stifle innovation and significantly delay project timelines.

This is precisely the challenge that virtual camera tools are designed to solve. AI-Innovate’s AI2cam is a powerful camera emulator that allows developers to simulate a wide range of industrial cameras and imaging conditions directly from their computer.

By decoupling software development from physical hardware, teams can build and test their applications faster, more affordably, and with greater flexibility. With a tool like AI2cam, engineers can rigorously test their algorithms across various scenarios before a single piece of hardware is purchased, empowering remote collaboration and accelerating the entire development lifecycle.

From Data Points to Intelligent Manufacturing

Ultimately, the most advanced application of automated visual inspection moves beyond simply accepting or rejecting individual products. The true transformative power of this technology lies in its ability to convert a stream of images into a rich source of actionable data.

Each detected defect is a data point that, when aggregated and analyzed, can reveal hidden patterns of inefficiency within the entire manufacturing process. This is where a solution like AI-Innovate’s AI2eye comes in. It doesn’t just find flaws;

it serves as an intelligent set of eyes on the factory floor, providing data-driven insights to optimize the entire production line. By identifying exactly where and when certain defects occur, AI2eye helps quality managers and operations directors move from a reactive to a proactive approach.

This enables them to address the root causes of problems, streamline workflows, reduce material waste, and boost overall efficiency, turning the quality control station into the data-driven nerve center of a truly intelligent manufacturing operation.

Read Also: AI-Driven Quality Control – Transforming QC With AI

Conclusion

The era of subjective, manual inspection is definitively closing. As we’ve explored, the convergence of high-fidelity sensors and adaptive AI provides a solution that operates at the speed of modern production with uncompromising precision. Automated visual inspection is therefore not merely an upgrade but a fundamental redesign of quality assurance. It establishes a new baseline for operational excellence, shifting quality from a goal to a guaranteed, embedded characteristic of every product that leaves the factory line, ensuring unshakable consumer trust.