In complex production and development cycles, unresolved flaws are more than mere errors; they are latent costs that erode profitability and operational integrity. Ignoring the origin of a defect is an invitation for its recurrence. Effective quality management, therefore, pivots from simply identifying symptoms to methodically dissecting their core origins.

At AI-Innovate, we enable this crucial shift from reactive fixes to proactive, intelligent problem-solving. This article moves beyond surface-level definitions to provide a functional roadmap of the most robust Defect Analysis Techniques, guiding you from foundational principles to data-driven and automated methodologies.

Foundations of Causal Investigation

The initial step in mature defect analysis is resisting the urge to implement a quick, superficial fix. The goal is to traverse the chain of causality down to its ultimate source. This requires a structured approach to questioning, a principle embodied by the 5 Whys technique.

It is a deceptively simple yet powerful iterative tool designed to uncover the deeper relationships between cause and effect, forcing a team to look beyond the immediate failure and identify the process or system breakdown that allowed it to occur. As we explore more complex scenarios, you’ll see how this foundational mindset becomes indispensable. The process is straightforward:

- Step 1: State the specific problem you have observed.

- Step 2: Ask “Why?” the problem occurred and write down the answer.

- Step 3: Take that answer and ask “Why?” it occurred.

- Step 4: Repeat this process until you arrive at the root cause—the point at which the causal chain can truly be broken.

Structuring the Analytical Process

When a problem’s origins are not linear and involve multiple contributing factors, more comprehensive tools are required to organize the investigation. These frameworks help visualize complex interactions and prevent cognitive biases from overlooking potential causes.

They provide a shared map for teams to navigate the intricacies of a failure, turning unstructured brainstorming into a systematic examination. Here, we delve into two of the most effective structural Defect Analysis Techniques.

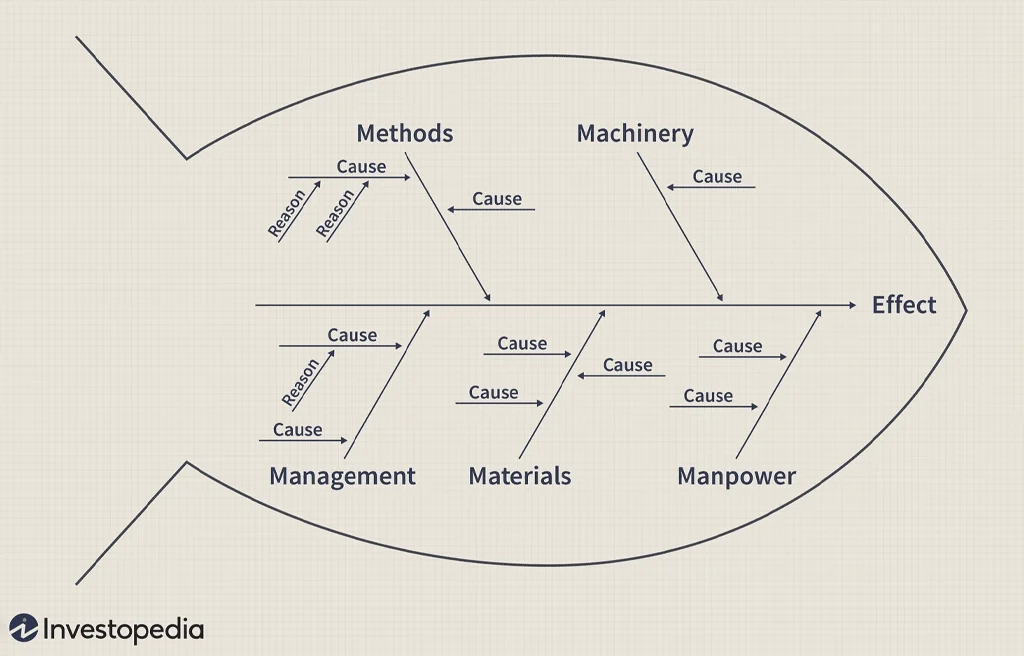

The Ishikawa Diagram

Also known as the Fishbone Diagram, this tool provides a visual method for categorizing potential causes of a problem to identify its root causes. By organizing ideas into distinct categories, it helps teams brainstorm a wide range of possibilities in a structured way. Key categories typically include:

- Manpower: Human factors and personnel issues.

- Methods: The specific processes and procedures being followed.

- Machines: Equipment, tools, and technology involved.

- Materials: Raw materials, components, and consumables.

- Measurements: Data collection and inspection processes.

- Mother Nature: Environmental factors.

Failure Mode and Effects Analysis (FMEA)

FMEA is a proactive technique used to identify and prevent potential failures before they ever happen. Instead of analyzing a defect that has already occurred, FMEA involves reviewing components, processes, and subsystems to pinpoint potential modes of failure, their potential effects on the customer, and then prioritizing them for action to mitigate risk.

Harnessing Data for Diagnostic Precision

While qualitative investigation points you in the right direction, quantitative data provides the validation needed for confident decision-making. Relying on intuition or anecdotal evidence alone can be misleading.

A data-driven approach transforms defect analysis from guesswork into a precise diagnostic science. This is where the Pareto Principle, or 80/20 rule, becomes invaluable. Pareto analysis helps teams focus their limited resources on the vital few causes that are responsible for the majority of problems.

For instance, by charting defect frequency, a team might discover that 80% of customer complaints stem from just two or three specific types of flaws, allowing them to prioritize corrective actions with maximum impact. To leverage this, a robust system for logging, categorizing, and tracking defects is non-negotiable, as this data feeds the entire diagnostic engine.

Evolving from Manual to Automated Inspection

For decades, manufacturing has relied on human visual inspection, a process inherently limited by operator fatigue, inconsistency, and high operational costs. The human eye, no matter how trained, cannot maintain perfect vigilance over thousands of products moving at high speed.

This is the critical bottleneck where minor defects are missed, leading to waste and potential brand damage. The industry is now moving toward AI-driven quality control as the definitive solution to these challenges. We are now entering an era where sophisticated Defect Analysis Techniques are embedded directly into the production line itself.

This evolution is embodied by AI-Innovate’s AI2Eye, an advanced system that integrates intelligent real-time defect analysis into the factory floor. It automates defect detection in manufacturing by using advanced machine vision to spot surface imperfections, contamination, or assembly errors that are invisible to the human eye. Discover how it transforms your operations:

- Drastically Reduces Waste: Catches defects the moment they occur, preventing the accumulation of scrap material and faulty goods.

- Maximizes Efficiency: Identifies production bottlenecks by analyzing defect data, offering insights to streamline the entire process.

- Guarantees Unwavering Quality: Ensures a consistently high standard of product, strengthening customer trust and brand reputation.

For QA Managers and Operations Directors aiming to eliminate the high costs and error rates of manual inspection, implementing an intelligent system like AI2Eye delivers a clear and immediate return on investment.

Streamlining Vision System Development

For the engineers and R&D specialists tasked with building tomorrow’s automated systems, the development lifecycle presents its own set of obstacles. Prototyping and testing AI inspection models often depend on securing expensive and specific industrial camera hardware, leading to project delays and significant capital expenditure.

Iterating on ideas becomes a slow, cumbersome process tethered to physical equipment. The ability to simulate real-world conditions is paramount for rapid innovation in machine vision for defect detection.

This is precisely the challenge that AI-Innovate’s AI2Cam is designed to solve. As a powerful virtual camera emulator, it decouples software development from hardware dependency, allowing your technical teams to innovate freely and accelerate their project timelines. With AI2Cam, engineers can:

- Achieve Faster Prototyping: Test and validate machine vision applications instantly without waiting for physical hardware to be purchased or configured.

- Reduce Development Costs: Eliminate the need for expensive cameras and lab setups during the development and testing phases.

- Increase Testing Flexibility: Simulate a vast range of camera models, resolutions, lighting conditions, and lens settings from a single workstation.

- Enable Seamless Remote Collaboration: Allow distributed teams to work on the same vision project simultaneously without needing to share or ship equipment.

For Machine Learning Engineers and R&D Specialists, AI2Cam is not just a tool; it’s a development accelerator that makes building the next generation of vision systems faster and more accessible.

Operationalizing Root Cause Analysis

Possessing a toolkit of analytical methods is only the first step. True organizational maturity is achieved when these techniques are embedded within a supportive operational framework. Without a standardized process and a culture that champions transparency, even the most powerful tools will fail to deliver results.

This involves creating a systematic workflow that ensures every significant defect is not just fixed, but also becomes a valuable learning opportunity. As you continue to refine your operations, you’ll discover which methodologies best suit your specific challenges. Here is a practical roadmap for implementation:

- Standardize Defect Reporting: Create a clear, detailed, and mandatory process for logging all defects, capturing crucial data from the outset.

- Prioritize for Impact: Classify defects based on severity, frequency, and business impact to ensure analytical efforts are focused where they matter most.

- Establish Cross-Functional Teams: Involve stakeholders from different departments (e.g., engineering, operations, QA) to gain diverse perspectives.

- Document and Share Findings: Maintain a central, accessible knowledge base of all RCA investigations to prevent recurring issues and institutionalize learnings.

- Foster a Blameless Culture: Frame defect analysis as a collective effort to improve processes, not to assign individual blame.

Synergizing Tools and Talent

The ultimate goal of implementing any technology is not to replace human expertise, but to augment it. In the realm of quality control, success is found in the synergy between skilled professionals and powerful analytical tools.

Even the most advanced automated system achieves its full potential when guided by experienced managers and engineers who can interpret its findings, make strategic decisions, and drive continuous improvement.

Investing in modern platforms for AI for quality assurance is a critical step, but it must be paired with an investment in training your talent. When your teams understand both the “why” behind the analytical methods and the “how” of using modern instruments, they transform from reactive problem-solvers into proactive architects of quality.

This powerful combination of human intellect and machine precision creates a resilient quality ecosystem and maximizes the ROI of your technological investments in Defect Analysis Techniques.

Conclusion

Mastering the spectrum of Defect Analysis Techniques is fundamental to transforming an organization’s approach to quality—shifting it from a costly, reactive posture to a strategic, proactive one. From the foundational logic of the 5 Whys to the data-driven precision of Pareto analysis and the automated intelligence of modern vision systems, each layer builds upon the last. At AI-Innovate, we stand as your dedicated partner in this evolution, providing the intelligent and practical tools required to embed efficiency and reliability deep within your operations.