The modern industrial landscape is not defined by its machinery, but by the colossal streams of data flowing from it. This transition from electromechanical operation to data-driven ecosystems marks the true essence of the fourth industrial revolution.

AI-Innovate exists at this critical juncture, providing the specialized intelligence to transform that raw data into tangible operational value. This article moves beyond surface-level discussions to dissect the core applications and strategic frameworks of machine learning, offering a clear roadmap for both industrial leaders seeking ROI and technical developers fueling innovation.

Unlock the Power of ML in Industry 4.0

Leverage cutting-edge machine learning to automate, optimize, and scale your smart factory today.

Process Intelligence via Production Data

The foundational promise of Industry 4.0 is the creation of systems that don’t just automate, but also learn and adapt. The raw output from sensors, production lines, and supply chains is, in its initial state, simply noise.

The true transformation occurs when this noise is translated into “process intelligence”—a deep, functional understanding of an operation’s health, efficiency, and vulnerabilities. This is the domain where algorithms act as the engine of cognition, identifying microscopic patterns in millions of data points that would be invisible to human oversight.

This intelligence is not an abstract concept; it directly translates to competitive advantage. By understanding the precise interplay between material inputs, machine settings, and ambient conditions, a manufacturer can move from reactive problem-solving to proactive optimization.

It represents a fundamental shift from asking “What went wrong?” to predicting “What is the optimal path forward?”. The implementation of Machine Learning in Industry 4.0 is precisely what enables this transition, turning historical and real-time data into a predictive asset that drives down costs and unlocks new efficiencies.

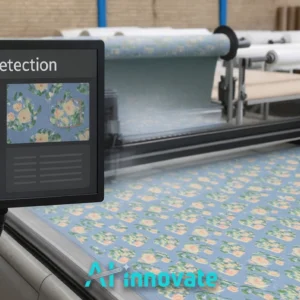

Automated Scrutiny of Surface Integrity

For Quality Assurance and Operations Directors, the ultimate goal is not just finding defects, but eradicating the conditions that create them. Manual inspection, constrained by human fatigue and subjectivity, presents a bottleneck and a point of failure in high-speed manufacturing.

Modern computer vision systems, powered by deep learning models, offer a solution that is not merely faster, but fundamentally more perceptive. These systems perform an automated, tireless scrutiny of surface integrity, capable of detecting sub-millimeter imperfections in textiles, metals, polymers, and other materials with absolute consistency.

This technological leap delivers a cascade of tangible business advantages that resonate directly on the balance sheet. For instance, advanced visual inspection platforms like AI2Eye are engineered to provide more than just defect detection in manufacturing; they are a tool for process control. Their impact includes:

- Drastic Reduction in Scrap Material: By identifying flaws in real-time, production runs can be corrected instantly, minimizing material waste and rework costs.

- Guaranteed Batch Consistency: Automated scrutiny ensures that every product leaving the factory adheres to the exact same quality standard, eliminating variance and strengthening brand promises.

- Fortified Brand Reputation: Delivering a verifiably zero-defect product builds immense trust with customers and solidifies a company’s position as a high-quality leader in its market.

Read Also: AI for Quality Assurance – Intelligent Manufacturing Insight

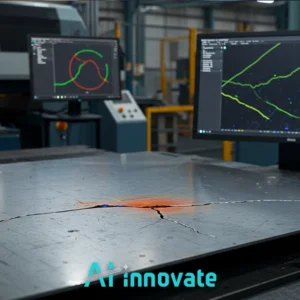

Operational Prognostics for Machinery

The financial drain of unplanned downtime remains one of the largest unresolved challenges in manufacturing. The traditional approach to maintenance has always been reactive. A machine fails, production stops, and repairs are made under immense time pressure.

The application of machine learning completely inverts this paradigm through the science of operational prognostics. This discipline focuses on predicting the remaining useful life of industrial assets, shifting maintenance from a reactive chore to a data-driven strategy.

By continuously analyzing data streams from equipment sensors—monitoring subtle changes in vibration, temperature, acoustic signature, and power consumption—ML models can identify the faint signals of impending failure weeks or even months in advance.

To fully appreciate this strategic shift, the operational differences between the traditional model and a modern prognostic framework are stark:

| Aspect | Reactive Approach (Traditional) | Prognostic Approach (ML-Powered) |

| Trigger | Equipment Failure | Data-driven Prediction |

| Focus | Rapid Repair | Failure Prevention |

| Outcome | Unplanned Downtime, High Costs | Scheduled Maintenance, Optimized Asset Lifespan |

This evolution makes the entire operation more resilient and cost-effective, cementing the strategic value of Machine Learning in Industry 4.0 for asset management.

Decoupling Innovation from Hardware

For the ML engineers and R&D specialists tasked with creating next-generation industrial solutions, the greatest inhibitor to progress is often not a lack of ideas, but a dependency on physical hardware.

The process of procuring, setting up, and testing with expensive industrial cameras is a significant bottleneck that consumes budgets and timelines. Each new experimental setup can mean weeks of delay, limiting the scope of innovation to only the “safest” bets.

This direct coupling of software development to hardware availability fundamentally constrains the speed of innovation. Freeing development from these physical shackles is the key to rapid, cost-effective, and truly agile R&D.

When developers can simulate any camera model, lighting condition, or production scenario from their own computer, the pace of prototyping accelerates exponentially. For ML engineers and R&D specialists facing these exact constraints, AI-Innovate’s AI2Cam offers a powerful camera emulation platform, enabling unlimited testing and validation in a purely virtual environment. This is how you start building faster, today.

The Regimen of AI Model Genesis

The path from raw industrial data to a deployed, value-generating model is not an act of magic but a disciplined, cyclical process. This journey, or regimen, is what separates successful AI implementations from perpetual “pilot projects.”

Understanding these stages is critical for any technical leader aiming to deploy robust Machine Learning in Industry 4.0 solutions. The foundational stages of this regimen include:

Data Acquisition and Annotation

This initial step involves collecting high-quality data from the target environment. For vision systems, this means capturing a vast and diverse set of images representing both normal and anomalous conditions. This data must then be meticulously labeled (annotated) to provide the “ground truth” for the model to learn from.

Feature Engineering for Industrial Signals

While some deep learning models can learn directly from raw data, industrial applications often benefit from feature engineering. This is the art of selecting, transforming, and creating the most informative signals from the data—for instance, extracting specific frequency bands from a vibration signal that are highly correlated with bearing wear.

Model Training and Validation

This is the core of the process, where the annotated data and engineered features are used to train the machine learning model. The dataset is typically split to train the model on one portion and then validate its performance on a separate, unseen portion to ensure it can generalize to new, real-world situations.

Finally, the regimen concludes with Deployment and Monitoring. This is where a validated model is integrated into the live production environment, often via robust APIs. The process, however, does not end at deployment.

Continuous performance monitoring against new data is critical to detect concept drift and trigger necessary retraining cycles, ensuring the model remains consistently accurate and reliable over time.

Towards the Sentient Production Line

As these technologies mature, the vision extends beyond isolated “smart” tools to the creation of a “sentient production line.” This concept describes a manufacturing environment that is not merely automated but is holistically aware, predictive, and self-optimizing. In this model, individual ML systems for quality, maintenance, and logistics act as the sensory nerves of a larger, centralized intelligence.

This integrated system doesn’t just execute commands; it perceives the state of the entire operation and makes autonomous decisions to improve it. Achieving this requires a seamless flow of high-fidelity data from every corner of the factory.

Real-time visual intelligence is a cornerstone of this architecture, acting as the “eyes” of the sentient line. The integration of robust platforms like AI2Eye provides the critical perceptual data needed to drive the adaptive, closed-loop quality control that defines this next evolutionary step in manufacturing, a testament to the integrated power of Machine Learning in Industry 4.0.

Read Also: Machine Learning in Quality Control – Smarter Inspections

Emergent Frontiers in Applied AI

While the applications discussed here represent the proven and practical state of industrial AI, the field is continuously advancing into new territories. Leaders in this space are not only mastering current technologies but also exploring the emergent frontiers that will define the factories of tomorrow.

These advanced domains are moving from academic research to applied solutions, promising even greater levels of autonomy and intelligence. Keep a close watch on developments in areas such as Digital Twins, which create a dynamic, virtual replica of an entire production line for complex simulation and “what-if” analysis.

Similarly, Federated Learning is gaining traction as a technique to train powerful models across multiple facilities without centralizing sensitive proprietary data. Finally, reinforcement learning is set to redefine robotics, enabling machines to learn optimal physical tasks through trial and error.

The ongoing developments in Machine Learning in Industry 4.0 are constantly pushing the boundaries of what is possible.

Conclusion

Embracing machine learning is no longer a speculative venture; it is a strategic imperative for competitive survival and market leadership in the industrial sector. From ensuring flawless product quality to predicting the health of critical machinery, the applications are tangible, measurable, and transformative. Realizing these benefits depends on choosing not just the right technology, but the right expert partner. AI-Innovate provides the specialized, practical tools that empower both industrial leaders and technical developers to turn the immense potential of Machine Learning in Industry 4.0 into their operational reality.