Legacy quality control often creates a data black hole. Defects are found, but the rich contextual data—the exact moment, machine state, or material batch involved—is lost. At AI-Innovate, we focus on illuminating these operational blind spots with intelligent vision systems that capture actionable insights.

This article is a technical exploration of Real-time Defect Analysis as a data-generation engine. We’ll detail how this methodology provides the granular, structured feedback necessary for true process optimization, moving beyond simple pass/fail checks to unlock a deeper understanding of production dynamics.

Catch Every Defect , As It Happens

AI that thinks and reacts in milliseconds.

The Obsolescence of Manual Inspection

For decades, the standard for quality control involved visual checks performed by human inspectors at the end of the line. While this method served its purpose in a different era, it is now a significant operational bottleneck in modern, high-speed production environments.

The core issue lies in its latency; defects are only discovered after significant resources—materials, energy, and machine time—have already been invested. This approach to Defect Detection in Manufacturing is fraught with inherent limitations that directly impact profitability and scalability. We can group these fundamental weaknesses into three main categories:

- Latency in Detection: Defects are identified long after they occur, making immediate root cause analysis impossible and leading to the mass production of faulty goods.

- High Operational Costs: The process is labor-intensive, subject to rising wage costs, and prone to inconsistency due to human factors like fatigue, training gaps, and subjective judgment.

- Data Voids for Analysis: Manual inspection rarely generates the structured, granular data needed for process optimization. Opportunities for systemic improvement remain hidden within anecdotal observations rather than actionable analytics.

The In-Process Verification Paradigm

The foundational shift away from outdated methods is the move toward in-process verification. This paradigm reframes quality assurance not as a separate station, but as a continuous, automated function embedded within every stage of production.

By leveraging intelligent systems, manufacturers can analyze product integrity in microseconds, turning the production line itself into a source of live quality data. Consider a packaging line for consumer goods: instead of a final spot-check, an AI-driven quality control system verifies the print quality, alignment, and integrity of every single label as it’s applied.

This transition from a reactive to a proactive model is the cornerstone of implementing a successful Real-time Defect Analysis strategy, effectively preventing defects rather than just catching them.

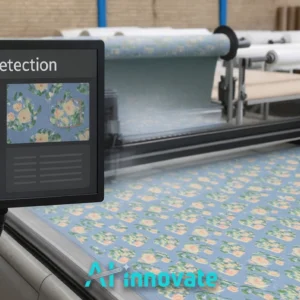

Machine Vision in Defect Scrutiny

At the technical core of this paradigm lies Machine Vision for Defect Detection. This discipline utilizes high-resolution industrial cameras, specialized lighting, and sophisticated algorithms to scrutinize products moving at high speed.

The system captures vast streams of visual data, which are then processed by machine learning models trained to identify minuscule deviations from a perfect “golden standard.” These are not simple rule-based systems; they learn the nuances of visual data to spot subtle flaws like contamination, texture inconsistencies, or micro-scratches that are often invisible to the human eye.

The adaptability of these systems allows them to be deployed across a wide range of industrial contexts. The versatility of this approach is best illustrated by its application across different materials, as detailed in the following table:

| Industry Sector | Common Defect Type | Specialized Inspection Technique |

| Polymer Film Production | Gels, “Fish Eyes,” and Carbon Specks | Backlit Transmission & Reflection Analysis |

| Paper & Pulp | Pinholes, Dirt Spots, and Formation Streaks | High-speed Laser-based Scanning |

Operationalizing In-Line Analytics

Implementing this technology goes beyond simply installing cameras; it involves integrating a new stream of intelligence into the factory’s operational nervous system. The output of an effective Real-time Defect Analysis system must seamlessly connect with existing Manufacturing Execution Systems (MES) and SCADA platforms to be truly effective.

This integration transforms raw defect alerts into actionable operational commands, such as ejecting a single faulty item or flagging a specific machine for immediate calibration. Deploying robust AI for Process Monitoring is critical for this step.

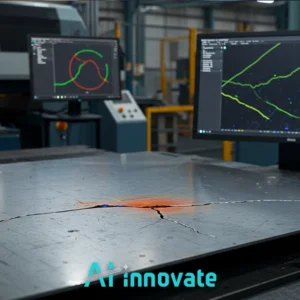

This data stream is far richer than a simple pass/fail signal. For each anomaly detected, the system generates a detailed data packet containing critical information such as precise X/Y coordinates of the defect, its physical dimensions, its classification (e.g., ‘scratch,’ ‘contamination,’ ‘misprint’), and a timestamp.

This high-fidelity data is what populates analytics dashboards, enabling quality teams to move beyond merely identifying a problem to performing rapid root-cause analysis. They can correlate defect patterns with specific raw material batches, machine settings, or operator shifts, unlocking a level of process insight that was previously unattainable.

Successfully embedding this technology into a live production environment typically follows a structured sequence of actions:

- System Integration & Workflow Definition: Map data outputs from the vision system to specific triggers within the MES, defining automated responses for different defect types and severities.

- Calibration and Baselining: Establish a “golden standard” reference by running known-good products through the system to define the acceptable range of process variation.

- Operator Training: Equip line operators with the skills to interpret the system’s interface and respond appropriately to its feedback, turning them into process supervisors rather than manual inspectors.

Accelerating Vision Prototyping

For the technical teams tasked with developing these systems—the Machine Learning Engineers and R&D specialists—the primary bottleneck is often hardware dependency. Procuring, setting up, and reconfiguring physical cameras and lighting for every new project or test scenario is both costly and time-consuming, significantly slowing the innovation cycle.

This is precisely where a virtual camera emulator becomes an indispensable tool. It allows developers to simulate a wide array of industrial cameras, resolutions, and lighting conditions entirely in software, decoupling algorithm development from hardware availability.

For development teams looking to break this cycle of dependency, a specialized tool like AI-Innovate’s ai2cam offers a powerful solution. It accelerates the entire prototyping and testing workflow, enabling faster iterations, remote collaboration, and dramatic reductions in upfront hardware investment.

From Anomaly Detection to ROI

For an Operations Director or QA Manager, the key question is how technical anomaly detection translates into measurable business value. A successful system moves beyond simply flagging flaws; it provides the data foundation for tangible improvements in financial and operational KPIs.

Each defect caught early is waste eliminated, a unit of scrap avoided, and a potential customer complaint averted. This is where an advanced Real-time Defect Analysis system demonstrates its full power, directly impacting the bottom line.

For organizations ready to translate in-line data into a measurable financial advantage, a comprehensive system like AI-Innovate’s ai2eye platform delivers on several key value propositions:

- Drastic Waste Reduction: Minimizes scrap by catching defects the moment they occur.

- Increased Production Throughput: Eliminates bottlenecks caused by manual inspection and rework loops.

- Enhanced Quality Assurance: Guarantees a higher, more consistent standard of product quality, protecting brand equity.

Navigating Implementation Complexities

Achieving a high-performing automated quality system requires navigating a set of technical challenges that demand deep expertise. Deploying a successful system is not a plug-and-play exercise; it is a meticulous process of engineering and data science.

Recognizing these complexities is the first step toward building a robust and reliable solution. Navigating this terrain requires expertise in several critical areas, from data strategy to model validation, and proficiency in advanced defect analysis techniques. We find that success often hinges on mastering the following domains:

Data Strategy and Annotation

The performance of any machine learning model is contingent on the quality of the data it’s trained on. This requires a robust strategy for capturing, storing, and accurately annotating thousands of images representing both good products and the full spectrum of possible defects.

A common challenge here is the “cold start” problem, where examples of rare but critical defects are scarce. An effective strategy involves deploying advanced techniques like few-shot learning, where models are trained to generalize from very few examples.

Furthermore, for development and pre-training phases, leveraging synthetically generated defect data is an increasingly powerful approach. By creating realistic digital models of defects and superimposing them onto images of good products, teams can build robust initial models even before extensive real-world data is available.

Model Tuning and Validation

An effective system must strike a precise balance between sensitivity (catching all true defects) and specificity (avoiding false positives). This demands rigorous model tuning and continuous validation against real-world production to minimize costly interruptions caused by false alarms.

Phased Rollout and Scaling

A “big bang” implementation across an entire facility is often risky. A more prudent approach involves a phased rollout, starting with a single critical line to prove the system’s value and refine its performance before scaling the solution factory-wide.

Conclusion

The era of end-of-line inspection as a viable quality strategy is over. Integrating Real-time Defect Analysis directly into the manufacturing process is no longer a competitive advantage but a necessity for survival and growth. This paradigm shift from reactive to proactive control delivers compounding returns in efficiency, cost reduction, and quality assurance. As a dedicated partner in this industrial evolution, AI-Innovate provides the specialized tools and expertise required to navigate this transition, helping manufacturers build smarter, faster, and more resilient operations.